Man Against Machine ~ Taking Assembly Screwdriving to the Next Level

Application Spotlight

An automated materials handling equipment manufacturer developed a production bottle neck. The operator had to install end caps onto a series of structural extrusions, and then secure each with four (4) screws. Due to the popularity of this product, production was having a tough time meeting demand.

During the initial application review, Visumatic discovered there were also some ergonomic concerns. Even though the screw was a fairly large #8 x 3/4″ long pan head, it was tough for the operator to sort and place the screw on the bit tip efficiently. This was causing some hand muscle strain and fumbling/dropping screws was increasing cycle time.

Visumatic solved both problems by eliminating the handling of the screw with a VLB-900-PS automatic screwfeeder. The machine instantaneously delivers the next screw to be driven to the tooling tip fully aligned, speeding things up for the user.

Now the operator’s only focus is making parts.

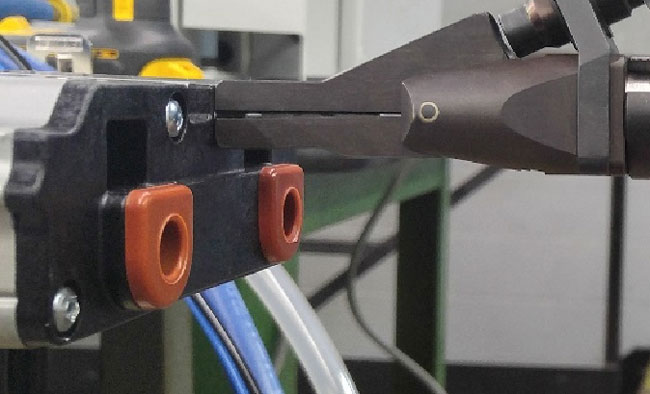

End Cap Being Screwed to Extrusion

End Cap Being Screwed to Extrusion VLB-900-PS Automatic Screwfeeder

VLB-900-PS Automatic Screwfeeder

Check out this fun video of two operators in a head-to-head race to see who can assemble parts faster. The best operator in the plant is on the left running screws manually the old way, with an inexperienced operator on the right using the VLB-900-PS automatic screwfeeder. Find out who wins and who loses in this quick real-life video taken on the shop floor.