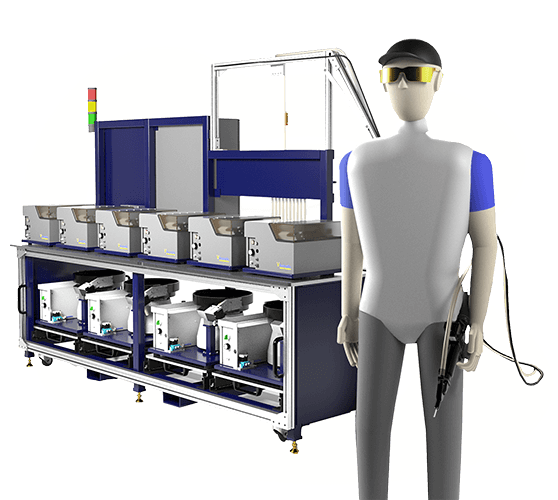

Multi-Fastener System

Multi-Fastener Automatic Screwdriver System

Application: Advanced screwdriving capability designed for high value parts requiring the highest degree of operator-utilized process control and monitoring.

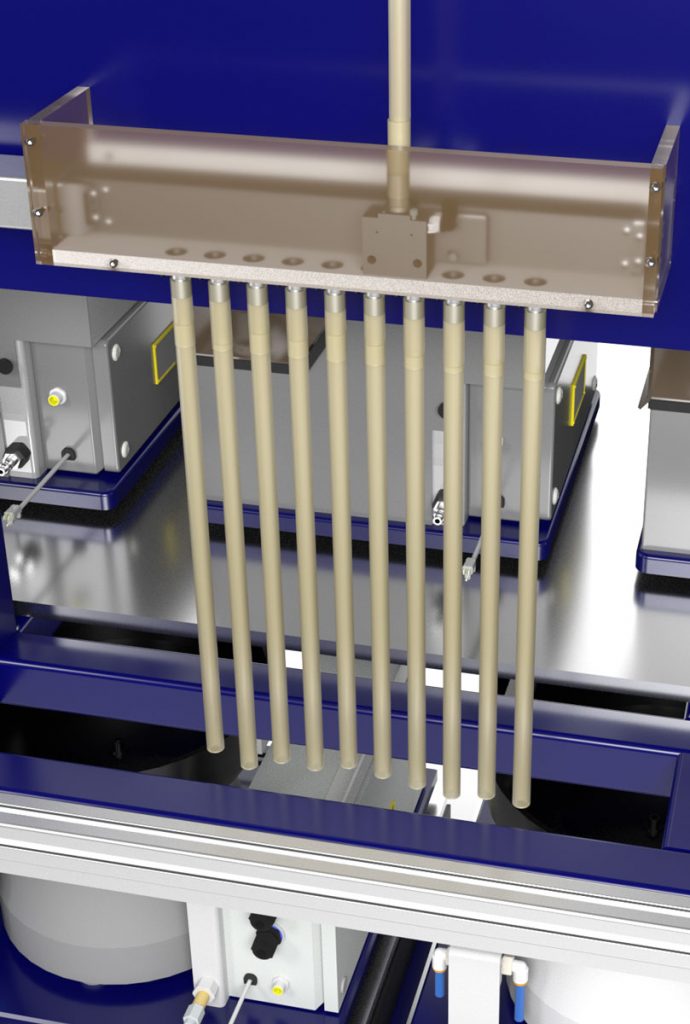

Visumatic developed the multi-fastener system to streamline efficiency in aerospace production allowing a greater level of ergonomics and quality control measures. Based around a many to one screw diverter mechanism, the system platform will allow a variable number of feeders to supply a single operator positioned automatic screwdriver.

Typical usage applications include the final attachment of aeronautic panels and projectile body housings. The precision fasteners used for these processes share a common diameter with variable gripping capabilities like screw shank length or thread pitch. Their use of a shared driver bit system enables full functionality with a single operator gun.

The multi-fastener automatic screwdriver:

- Improves ergonomics eliminating operator screw handling

- Speeds production directly delivering proper fastener

- Reduces opportunities for bonus or incorrect screws

The required feeder system can be selected directly “on the fly” by operator choice. Assembly qualification can be enhanced by coordinating with the customer’s existing optical or bar code scanning system. Configuration options include the ability to auto-select the fastener type remotely in conjunction with the plant network PLC.

The Visumatic system can be programmed to provide batch and rundown data to the plant MES network for complete SPC data collection.

A screw will only be automatically delivered to the operator tooling after an OK target torque output and batch count confirmation. A visual light tower with audible device alerts will indicate system status to the operator and near-process personnel.

The Visumatic Advant-edge

Increases quality assurance while moving from a labor-intensive two-step drive with re-torque operation to a single auto-feed rundown process with simultaneous torque and angle control.

This complete feed and drive package includes our most ergonomically advanced handheld system. The VZP automatic screwdriver extends the screw from the tooling tip, making it an exceptional no-mar choice for finished or advanced composite surfaces.