VPS Screw Presenter

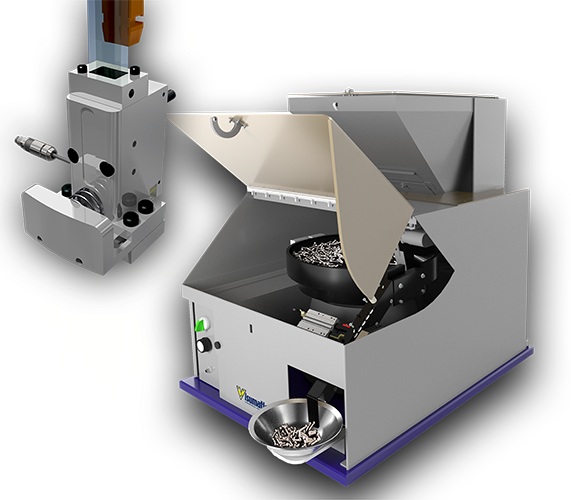

VPS Screw Presenter System

Application: Sorts bulk fasteners and presents them for pick up by an operator or robot tool.

Screw presenter systems take over the counting and manipulation of bulk fasteners for manufacturers. The screws are dispensed to a pre-determined count or presented one at a time for use by an operator.

The VPS system can be configured to handle extremely difficult fastener geometry. Screws are bulk loaded into the system supply hopper, and the machinery sorts, orients, and presents a single fastener for human or robot pick up.

The Visumatic Screw Presenter Advant-edge

- Advanced controls.

- Configured to fit your fastener and process needs.

- Longest remote blow distance on the market.

The included standard feeder control package allows variable or fixed count dispensing. The feed process is initiated via on-board sensors or remotely via a PLC feed signal.

Presenter Designs to Handle Many Fasteners:

Screws * Nuts * Pins * Washers

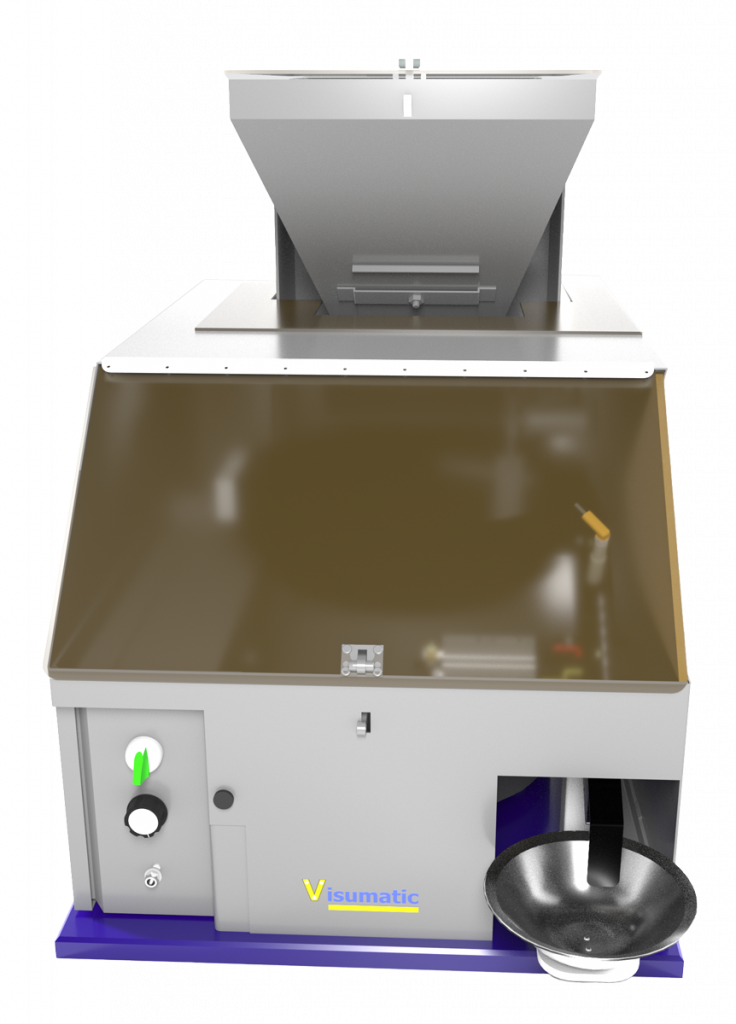

VPS – Local Pick Up Screw Presenter

The system is placed inside the assembly are for use by an operator. Screws are dispensed into the pick-up dish in the programmed quantity. An operator will remove the fasteners with a hand swipe and the system will detect that action, automatically loading the dish for the next batch pick-up.

The system delivers an ergonomic advantage taking the finger strain of sorting and manipulating screws for the operator. Dropped or wasted screws are greatly reduced improving workspace safety and driving down material costs.

The VPS Local screw presenter can also be configured for use with a portable take-out tray. The system dispenses the pre-determined quantity into a bin. When required, the operator can remove the bin and take it to another location for usage. When an empty bin is placed back into position, the system will automatically present the next batch or optionally wait for a button push activation.

The configuration possibilities are endless!

Configuration Options

- VPS Remote Screw Presenter

- VPS – Direct Human Pick

- VPS – Direct Robot Pick

- VPS – Hybrid Remote/Direct

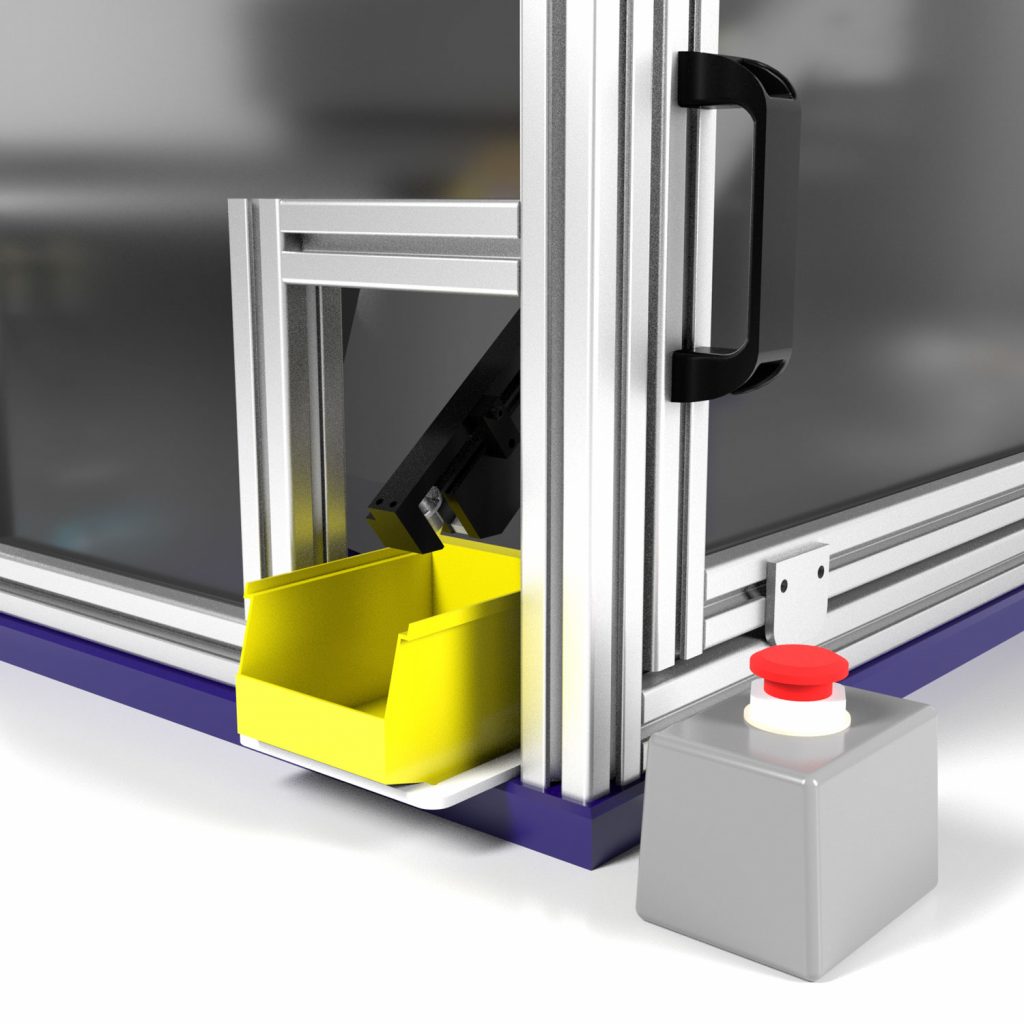

VPS Remote Screw Presenter

Using the same reliable feeder and control platform, the VPS Remote Screw Presenter will sequence and deliver the correct number of screws to a remotely mounted receiver. The operator depresses the button allowing the batch quantity to be released into their hand. Typical feeder placements range from 5 to 50 feet away allowing floor space flexibility while keeping operator steps to a minimum.

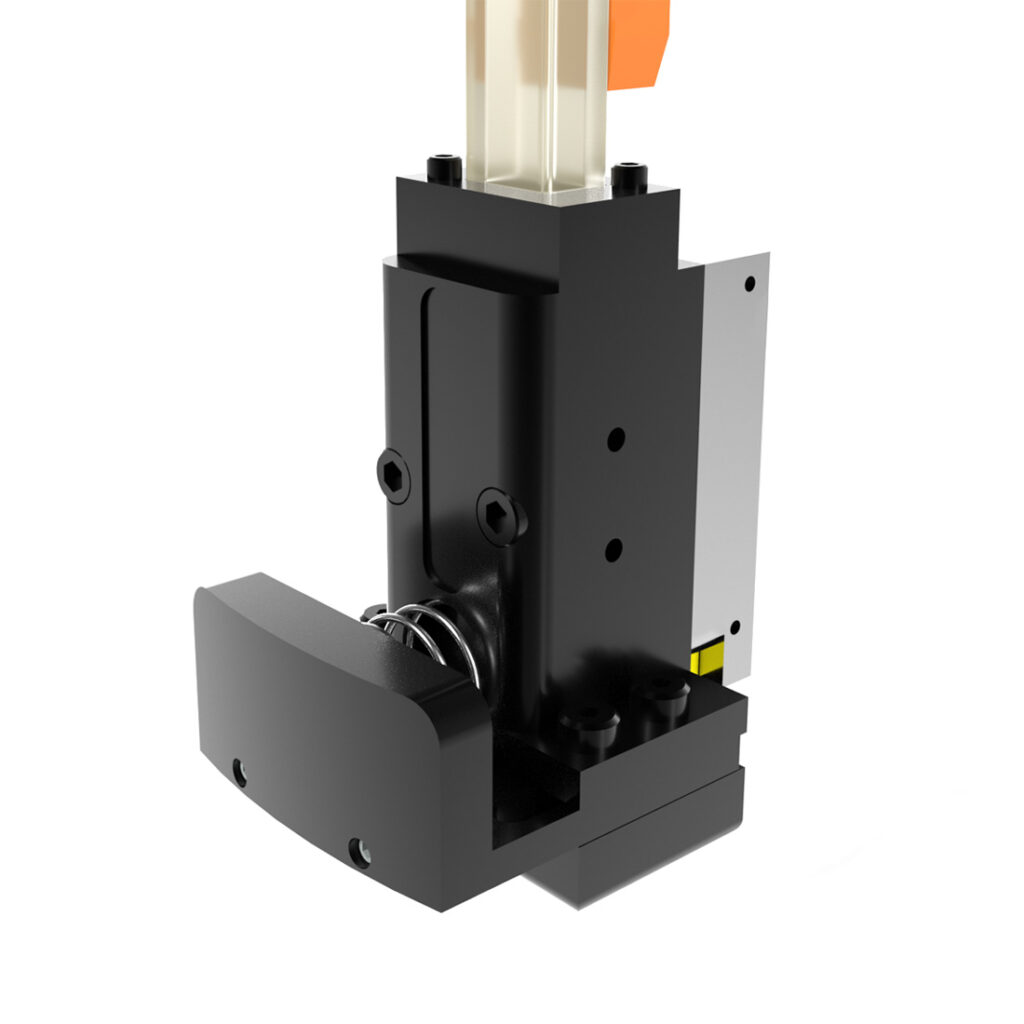

VPS – Direct Human Pick

This screw presenter package cingulates and presents one fastener per cycle. An operator brings the motor to the feeder using a magnetic bit to engage the screw, removing it from the escapement. They then move their driver bit and screw to the work-piece to install the screw.

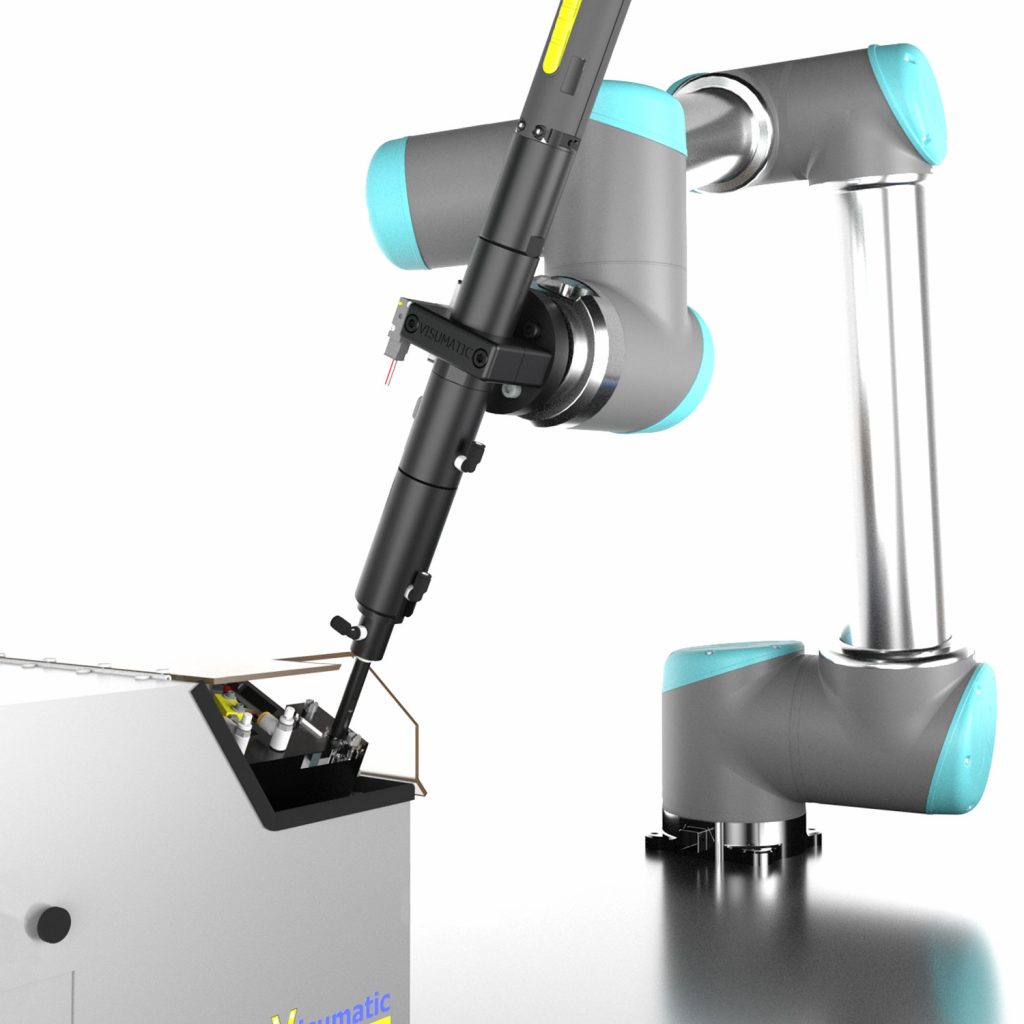

VPS – Direct Robot Pick

This screw presenter system has the ability to singulate a fastener and position it for robot pick up. The feeder includes I/O to allow remote feed and pick confirmation sensing.

VPS – Hybrid Remote/Direct

The Hybrid screw presenter is engineered for assembly machines with limited space or high levels of mechanical activity. The feeder remains outside the general workspace sending fasteners into the machine. A remote direct pick receiver is place inside the robot work envelope, saving time and valuable space.