Lights-Out Screwdriving

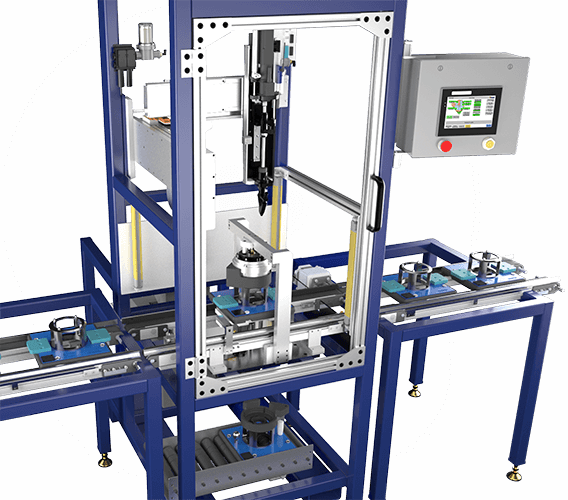

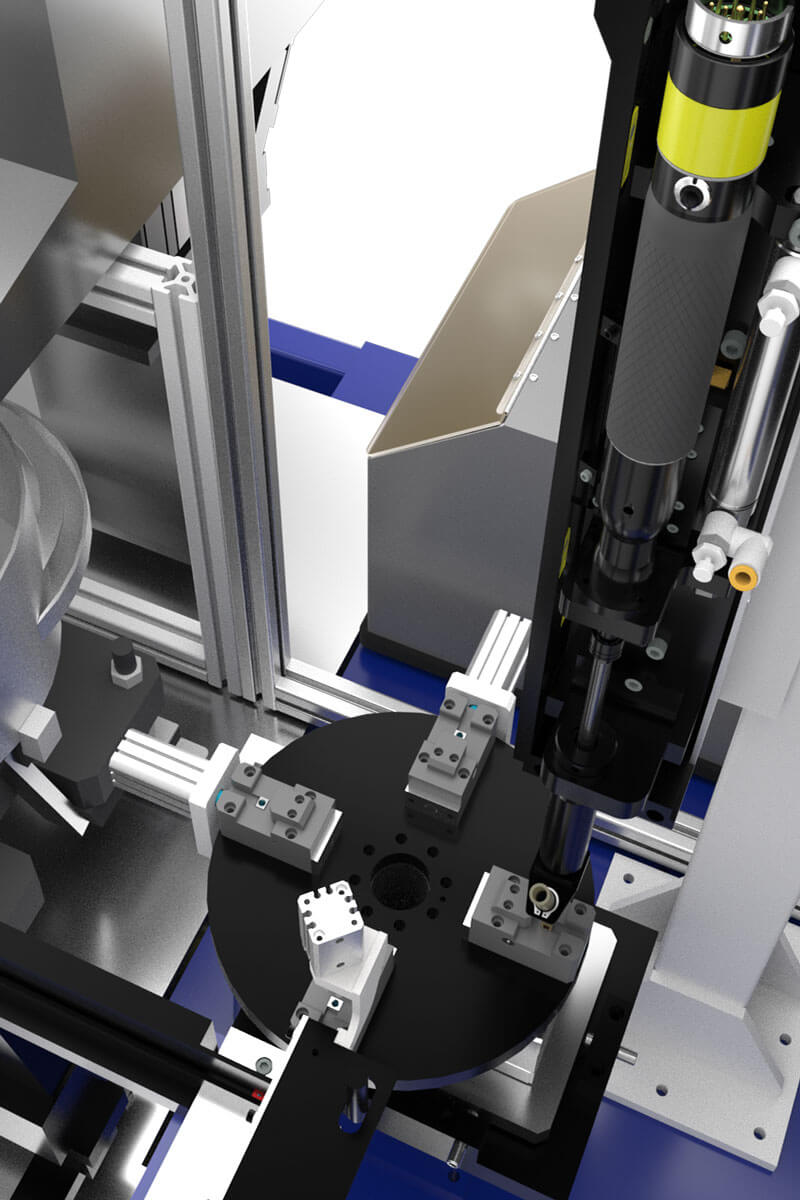

Application: Fully automated assembly machines with parts presented to the automatic screwdriving system for rapid throughput fastening.

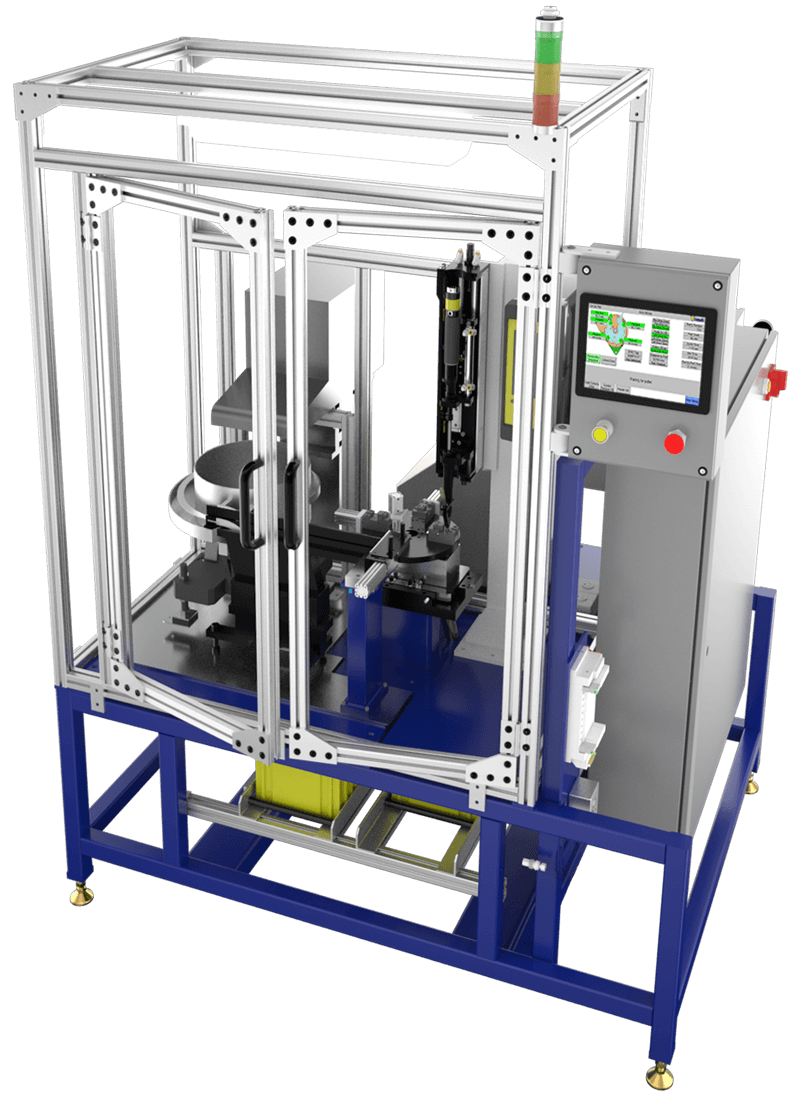

Our lights-out screwdriving platforms allow you to launch new products faster while producing qualified assemblies at higher speeds.

While humans still perform 72 percent of manufacturing tasks, Visumatic’s mission is to educate product designers and arm process improvement engineers with the proper automation screwdriving technology. Standard designs include built-in scalability paving the way to implement new machines in the future.

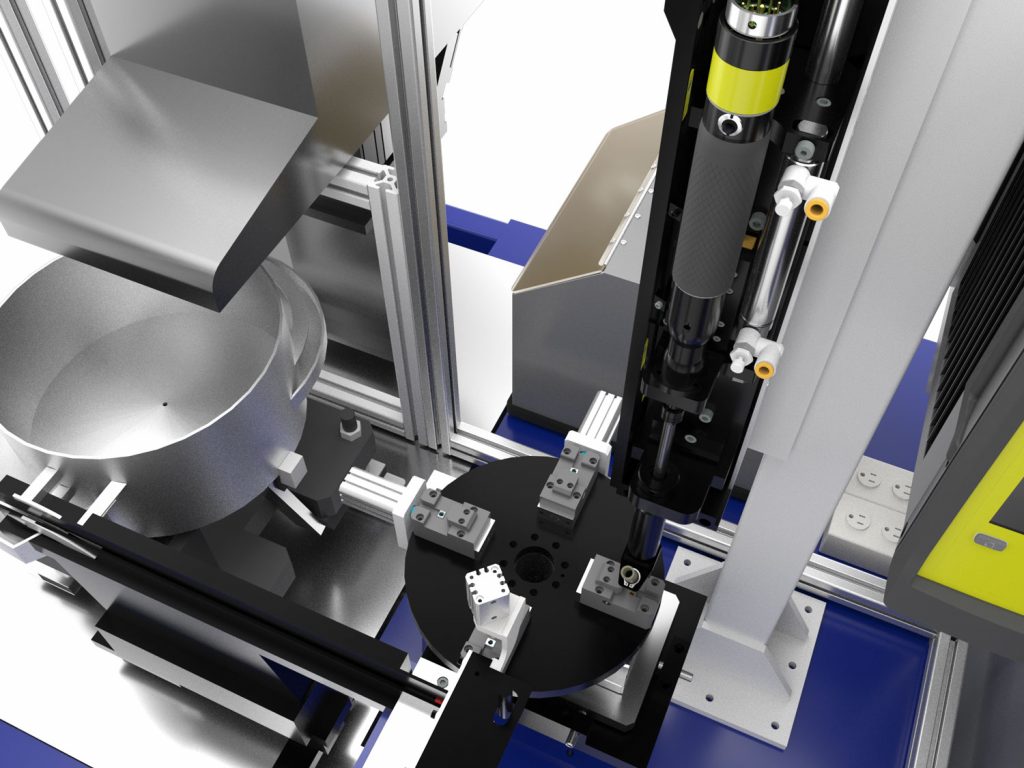

The machines can work unattended with no humans involved in the screwdriving process. Parts can be conveyor fed or bulk loaded while the machine subsystems orient and deliver them to the screwdriving station. Multi-nest rotary indexing systems are the most popular high throughput method for small part assembly.

The Visumatic Advant-edge

Featured-packed technology packages that grow with your assembly line.

Light-out screwdriving is not practical for every application. Mating sub-assemblies with no locating features are not suitable for automation because operators remain the most flexible way to perform dynamic orienting tasks. When parts are properly designed, Visumatic’s streamlined screwdriving platforms make deciding to automate easy.

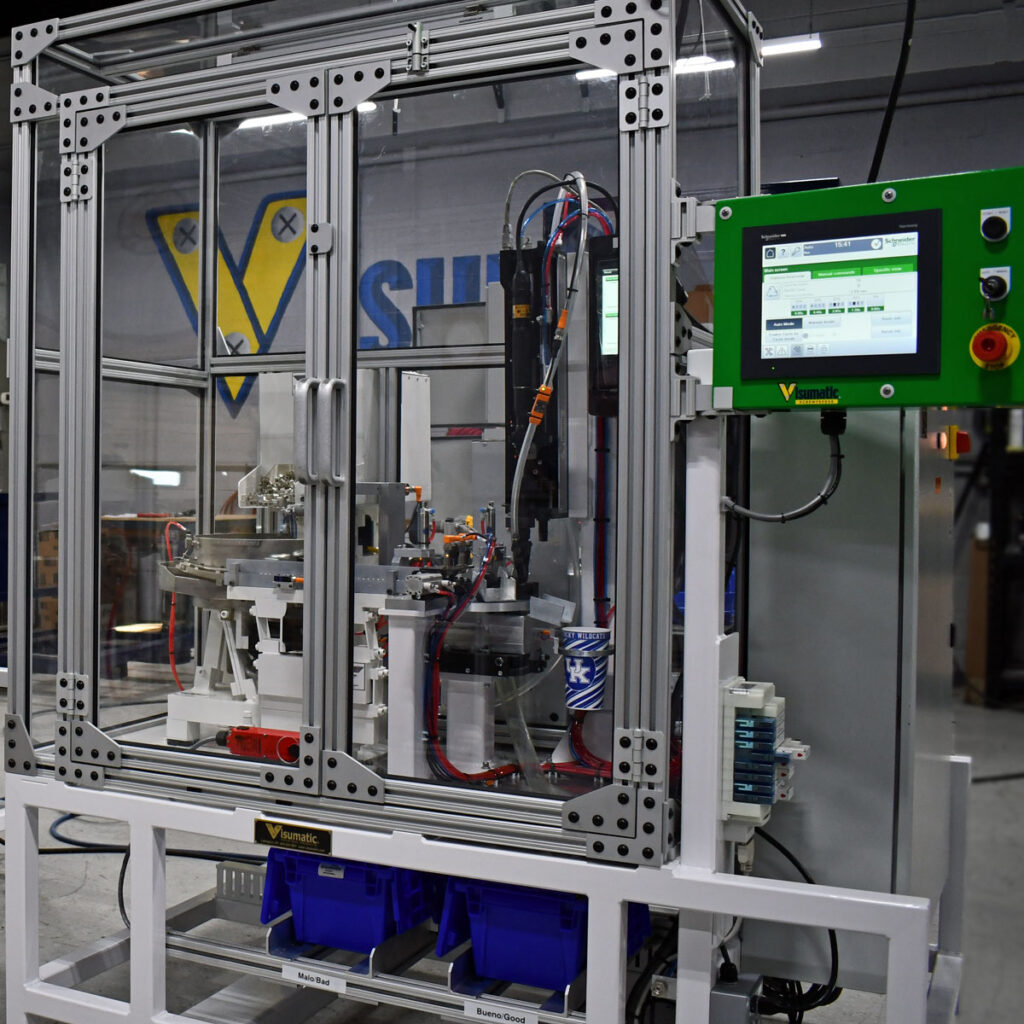

Every lights-out screwdriving systems can be built to include:

- Automatic fastener feed and drive system

- Local or networked data reporting

- Torque and angle control screwdriving

- Rotary index or conveyor fed parts on-boarding

Visumatic’s assembly machines are optimized for rapid assembly and built-in quality assurance. Tooling and jigs are designed to match your unique components. Every aspect of the build conforms to your specifications so the machine comes ready to plug and work. Factory start up assistance and maintenance training are available for every lights-out screwdriving system.

Visumatic lights out screwdriving machines are configured for your process, with the best choice of:

- Screwdriver Motor: Pneumatic or DC Electric Torque Control

- Nosepiece: Fin-Jaw, Standard, or Nut-Jaw

- Escapement: Standard, Cam, Siamese, Nut, or Finger

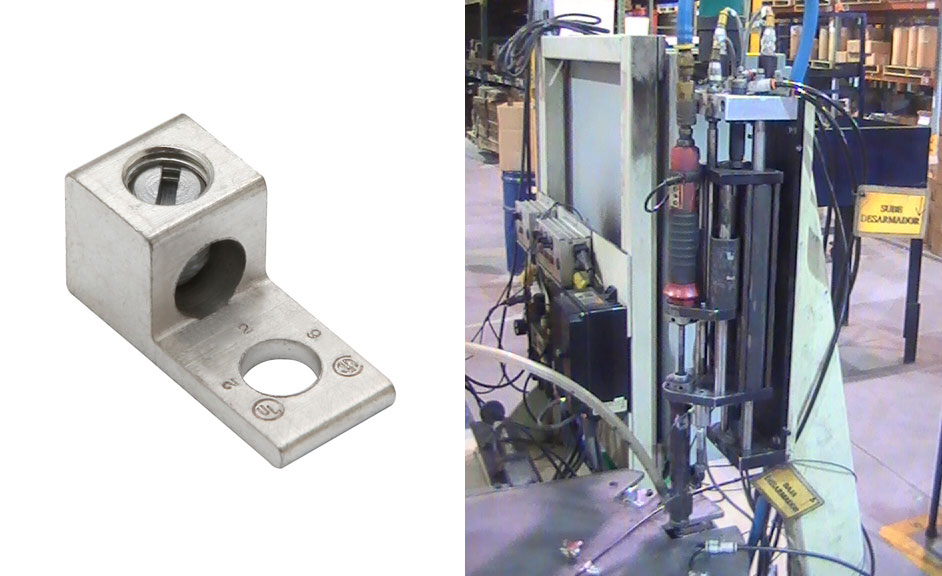

CASE STUDY

Never-Stop Assembly Machine Hits 20-Year Production Mark

An electrical lug manufacturer came to Visumatic in 1999 looking to reduce labor and radically improve throughput for a mature product. A rotary indexing system was created, combining a single VPD Power Driver and a set of Model 94 feeders.