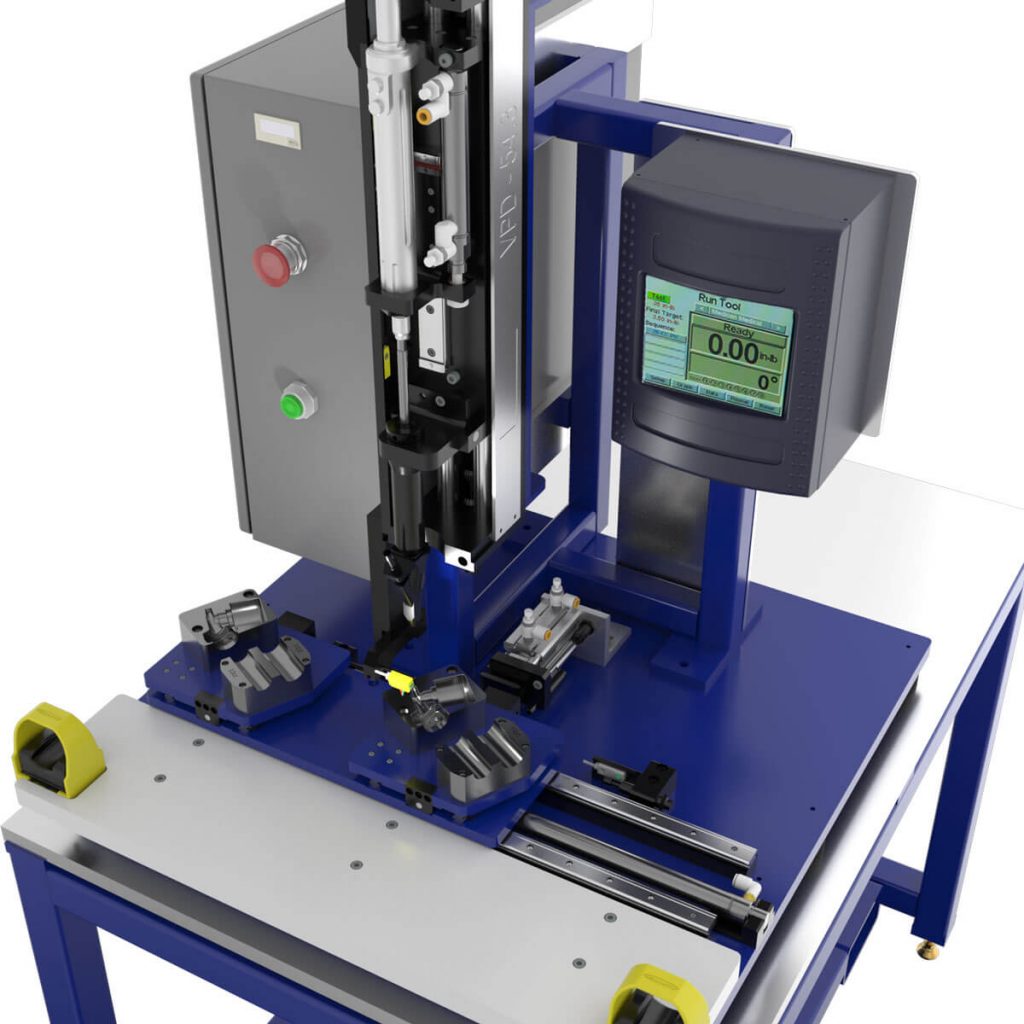

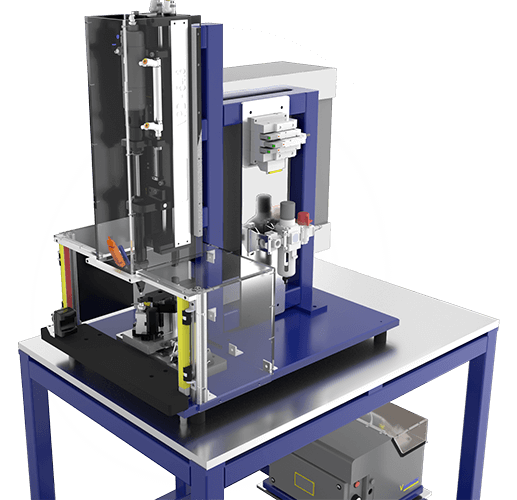

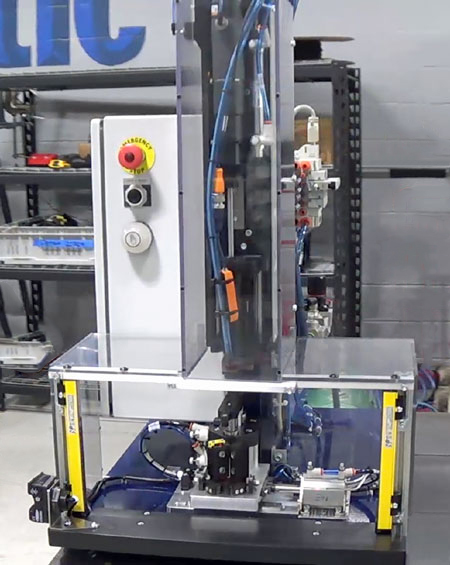

Tabletop System

Application: Flexible screwdriving system provides qualified assembly and throughput gains in a simple tabletop package.

Tabletop screwdriving machines are the next step up in assembly process automation, making a seamless transition from handheld fastening. These machines feature full assembly control with custom tooling that holds each work piece and a screwdriver that actuates for driving.

An operator places the components in position and starts the assembly process, which can involve installing multiple fasteners in tandem where needed. When the cycle is complete, the operator removes the completed assembly and repeats the process.

Tabletop Screwdriving Systems include:

- Basic to advanced part fixturing

- Automatic feed and drive fastening components

- Operator interface with system status and part counters

The straight-forward machine control platform monitors the screwdriving process helping to ensure a quality assembly. The immediate productivity gains and low capital outlay allow for a quickly attainable ROI.

The Visumatic Advant-edge

- Place-anywhere functionality for flexible work cell arrangement

- Ready to make parts out of the box

- Immediate ergonomic and throughput gains

Configured to fit your application, our process engineers will develop an assembly solution to maximize your productivity gains. Options for single fastener, multi-spindle, and actuating part fixtures allow the highest customization level available on the market today.

Visumatic Tabletop Screwdriving Systems are engineered for your process, with the best choice of:

- Driver: Pneumatic or DC Electric Screwdriver

- Nosepiece: Jaw, Mini-Jaw, or Fin-Jaw

- Escapement: Standard, Cam, Nut, Clip, Finger, or Siamese

CASE STUDY

Tabletop Screwdriving Machine Instantly Doubles Production

A fluid control manufacturer was faced with the challenge of increasing throughput without adding labor. The valve body had two screws per part, with a multi-component stack up that included a spring. This made consistent fastening very challenging for an operator doing manual assembly.