VLB-900 Locking Bit

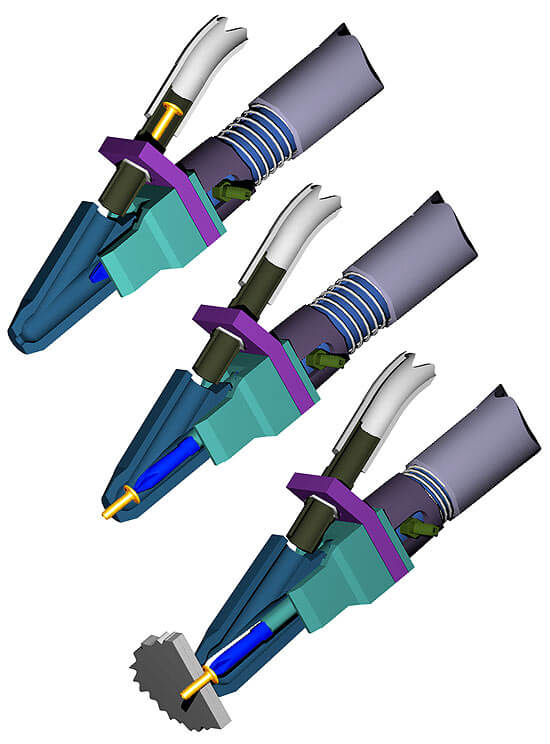

Application: Positively engages screw in the nosepiece tooling tip so operators can align mating parts in any orientation.

The Locking Bit is Visumatic Industrial Products’ basic automatic screwfeeder. It’s the simplest, most reliable handheld screw feeding and driving system on the market. Visumatic invented the Locking Bit automatic screwfeeder with over 20 years of research and development.

Our exclusive design:

- Keeps the bit and screw engaged in the nosepiece

- Operator can align the parts prior to fastening using the screw to feel the joint

- Allows vertical, horizontal and inverted application

- Pistol Grip or Inline assemblies

- Operator can ‘ice pick’ the assembly ensuring proper alignment, for seamless application and maximum productivity

The Visumatic Advant-edge

- Advanced microprocessor controls

- The simplest, most reliable and efficient feed system available

- One Movement, Zero Adjustments

- No external springs or pins hold the nosepiece together

- Steel enclosure limits sound and debris

- Longest blow distance on the market

- Greater control and capability

- Nosepieces designed to fit your part, control the screw, keep bit & screw engaged

Visumatic Locking Bit systems are designed for your part, with the best choice of:

- Drive Motor: Pneumatic, AC or DC Electric Torque Control

- Nosepiece: Jaw, Finder, Mini, or Nut-Jaw

- Feeder Escapement: Standard, Nut, Cam, or Finger

- Driver Style: Inline or Pistol Grip Lever, Trigger or Push-to-start

- Optional Ergonomic Torque Arm & Bulk Supply Hoppers

Greater speed and ergonomics for operator acceptance.

CASE STUDY

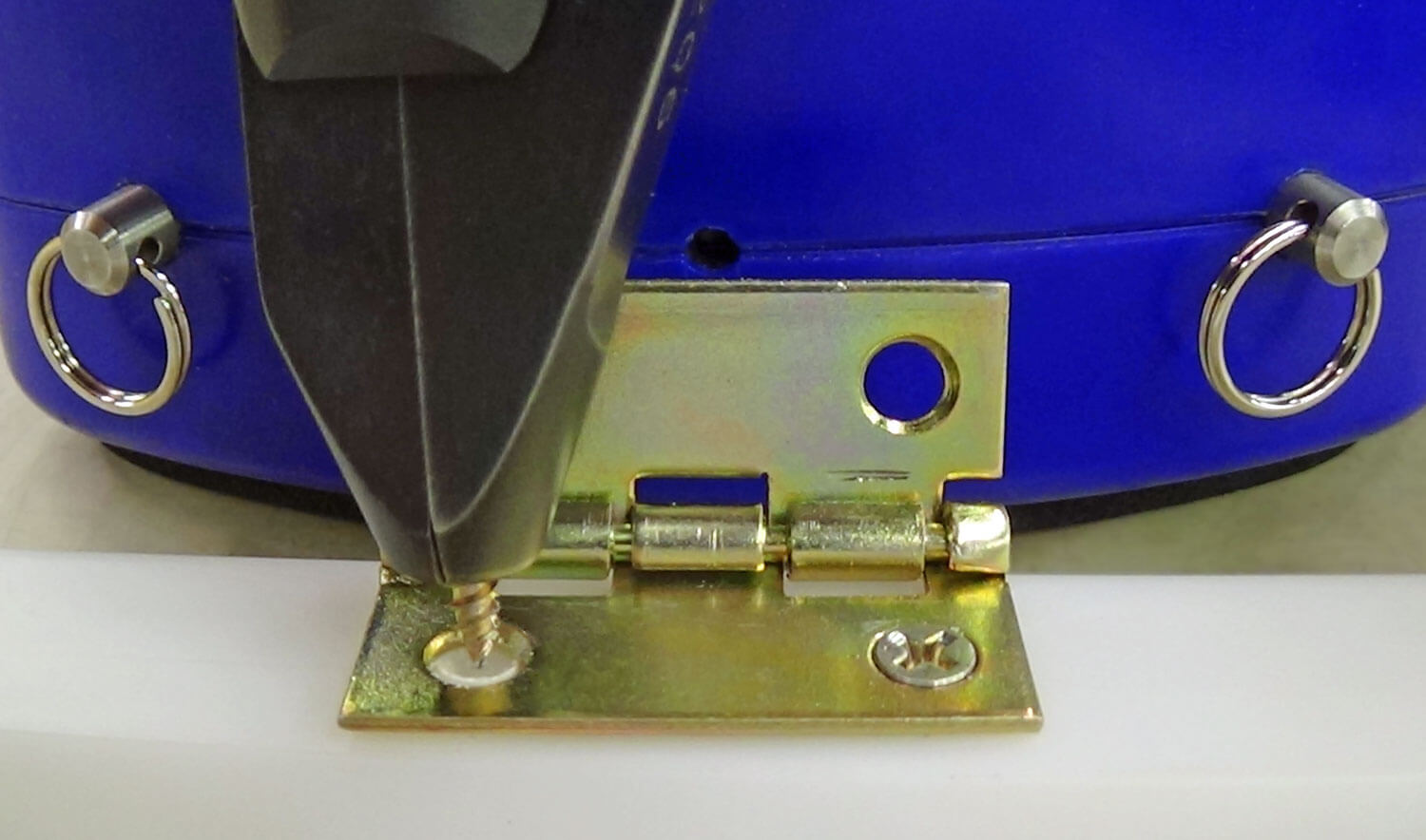

Handheld Screwdriving System Helps a Hamper Manufacturer Double Production

A long time Visumatic customer manufacturing laundry hampers has been experiencing sustained sales growth. Production was given the task of nearly doubling production of this product at their facility. The application is to drive two #6 flat head screws into a metal lid hinge.