Custom Fastener Insertion

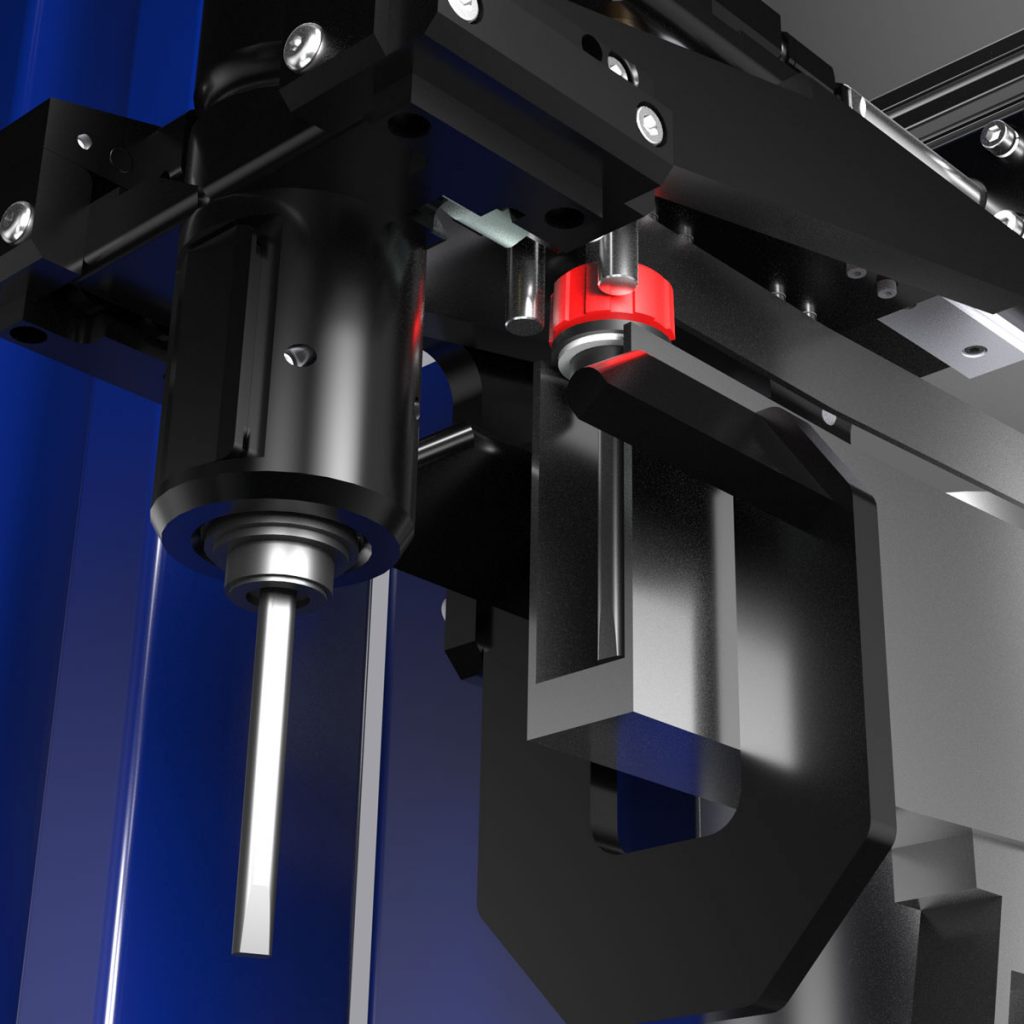

VIM-400 Custom Fastener Insertion System with Automatic Feeder

Application: Automatic feed insertion package for machine builders that quickly feeds and reliably inserts a variety of specialty fasteners to proper depth.

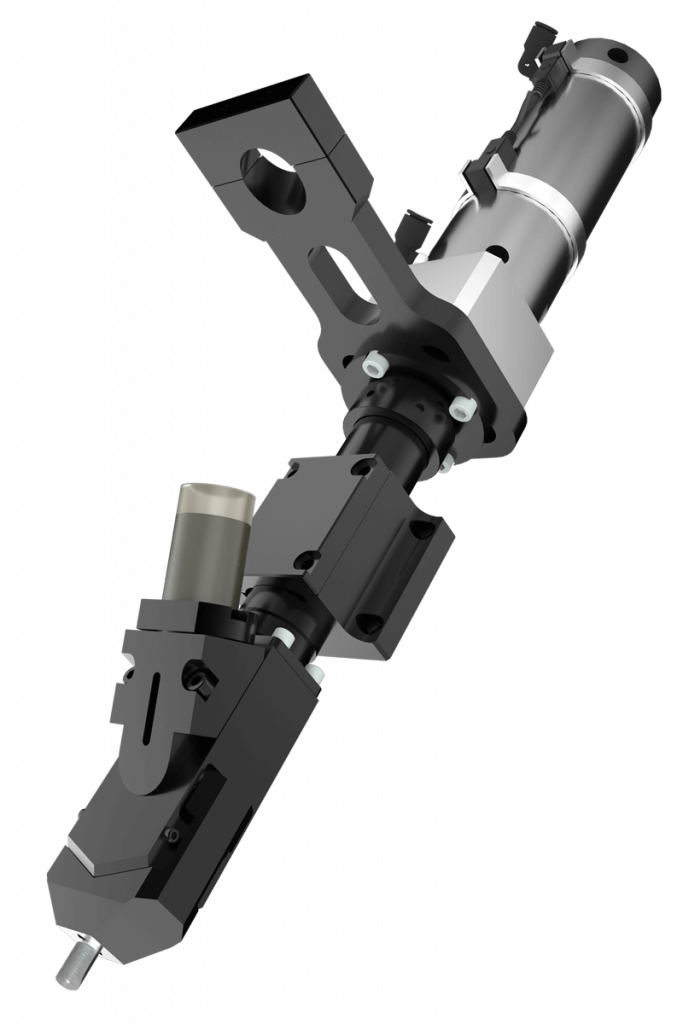

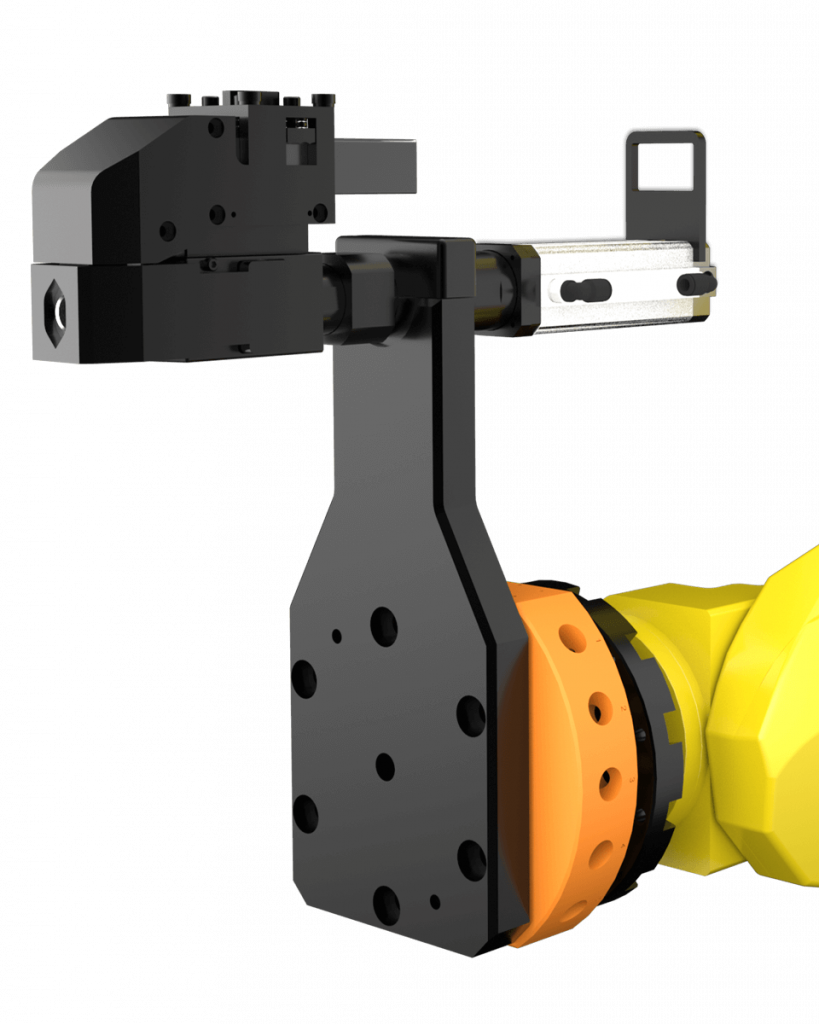

Flexibly engineered for use in most robotic integrations, the VIM-400 can be used with 6-axis and cartesian robot assembly machines. Custom designed tooling built to automatically feed place a wide range of non-threading fasteners such as nails, wooden dowels, rivets, studs, and many other types of specialty fasteners.

The Visumatic Advant-edge

Custom engineering ~ the possibilities are endless.

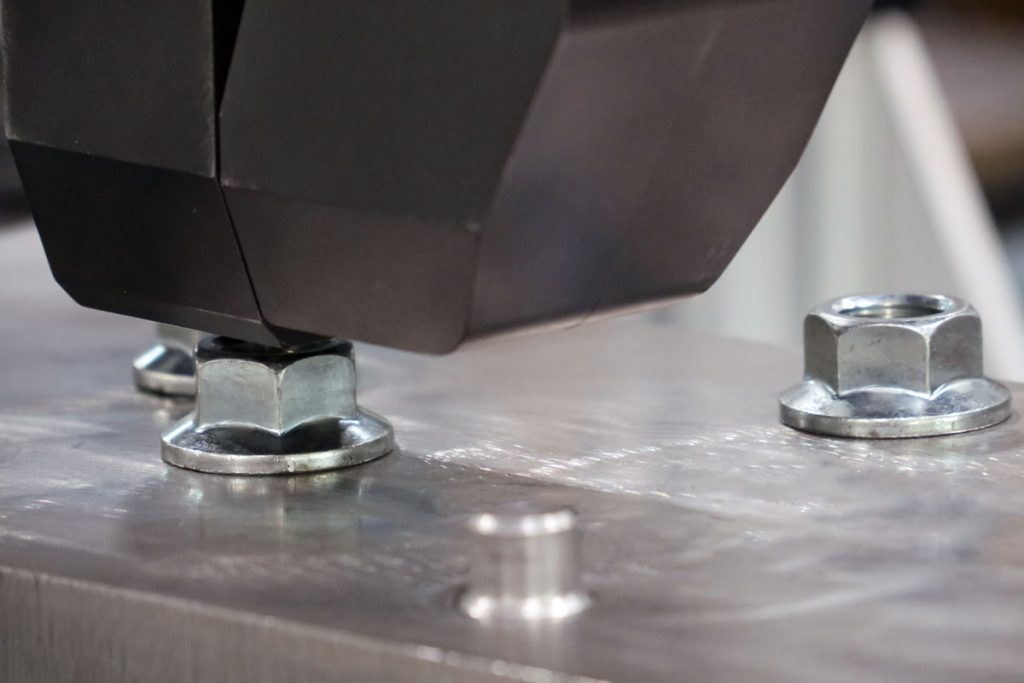

Flexible mounting options allow for direct robot EOAT installation with a customized adapter plate that matches your actuation method. Tooling tips are custom engineered to interface with component surface details allowing maximum assembly efficiency and accuracy.

Custom fastener insertion systems include:

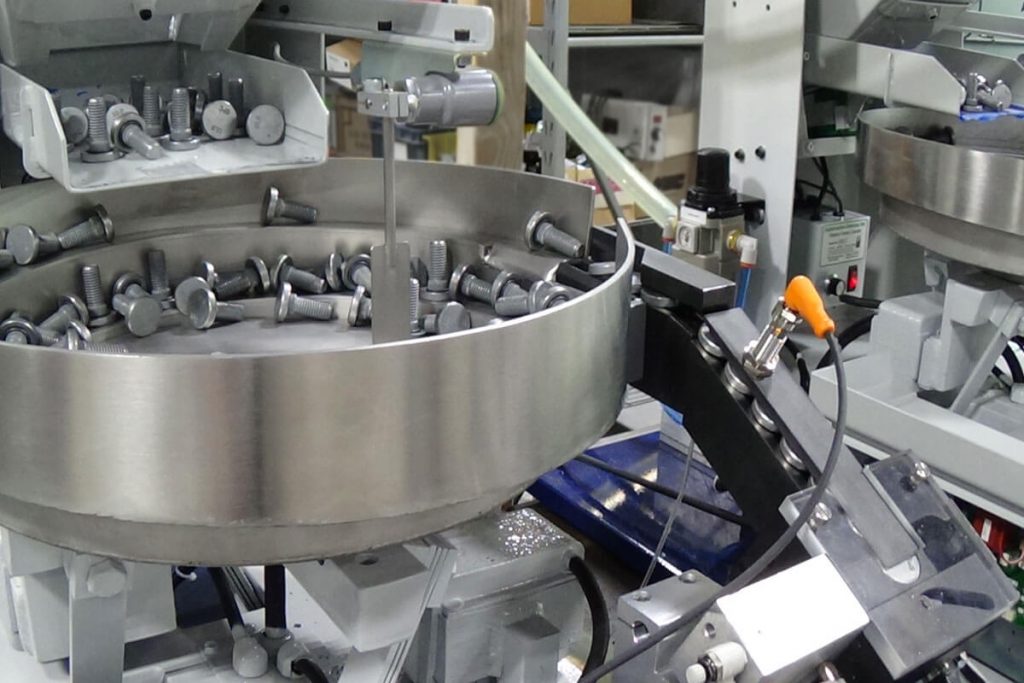

- Self-contained Model 94 automatic feeder system

- Steel enclosure to limit sound and non-conformance items

- Transfer sensor that provides feed to tip confirmation

- Tooling designed to interface with your fastener and part

Integrated punch position sensors provide real-time feedback to the machine PLC. This adds another layer of process qualification by verifying insertion depth, improving cycle reliability.

Visumatic specialty fastener insertion spindles have nosepiece designs to place a wide variety of non-threading fasteners:

- Wooden dowels

- Rivets and knurled studs

- Standard or weld nuts

Engineered capability to handle any fastening challenge you face.

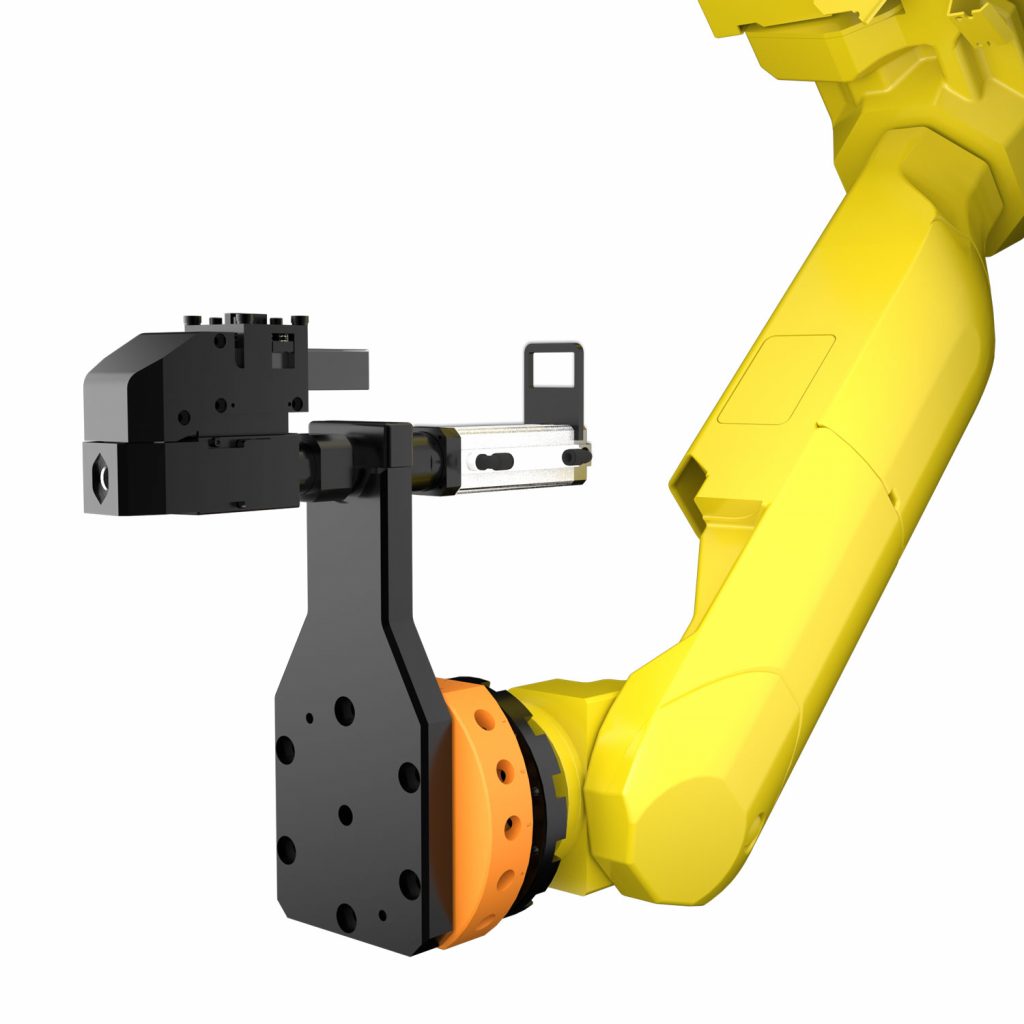

VIM-800 Nut Insertion System for Complex Assembly

Application: A robust package for machine builders that feeds and inserts nuts for integrations utilizing motion hardware to present the parts or insertion module.

The VIM-800 nut insertion system fits when you need the nut socket-stroked onto a stud or into a mold cavity. The only actuation is the punch, so the insertion module is dependent on other machine components for presentation motion.

You can present the part to the nosepiece or mount the insertion head on your linear positioner to achieve the desired Z-axis relationship between the nosepiece and the insert location. The VIM-800 automatic nut insertion system is the in-house builder’s most popular EOAT choice for 6-axis robots.

The Visumatic Advant-edge

Rapid fire nut feed direct to insert point for repeatable insertions.

There’s more to our excellence than efficiently and reliably performing automatic nut insertion. The design features and easy integration of our systems speak to the worry-free maintenance and low cost of ownership. Rugged sized-right cylinders with included flow controls give your end user the peace of mind that comes with long lasting componentry.

Integrated punch stroke position sensors ensure that proper seating depth is achieved. Self-aligning socket features help locate the target and keep the nut flat during the insertion process.

Rapid Deployment Nut Insertion Bundle Includes

- Feeder enclosure for cleanliness and sound reduction

- Nut transfer sensor with cable

- Built-in socket stroke position sensors

- Microprocessor controlled Model 94 nut feeder

The nut insertion spindle comes complete with a fastener transfer sensor to confirm nut delivery to the module. Tooling tips are custom engineered to interface with componentry details for repeatable and accurate placement.

Your parts dictate our design.