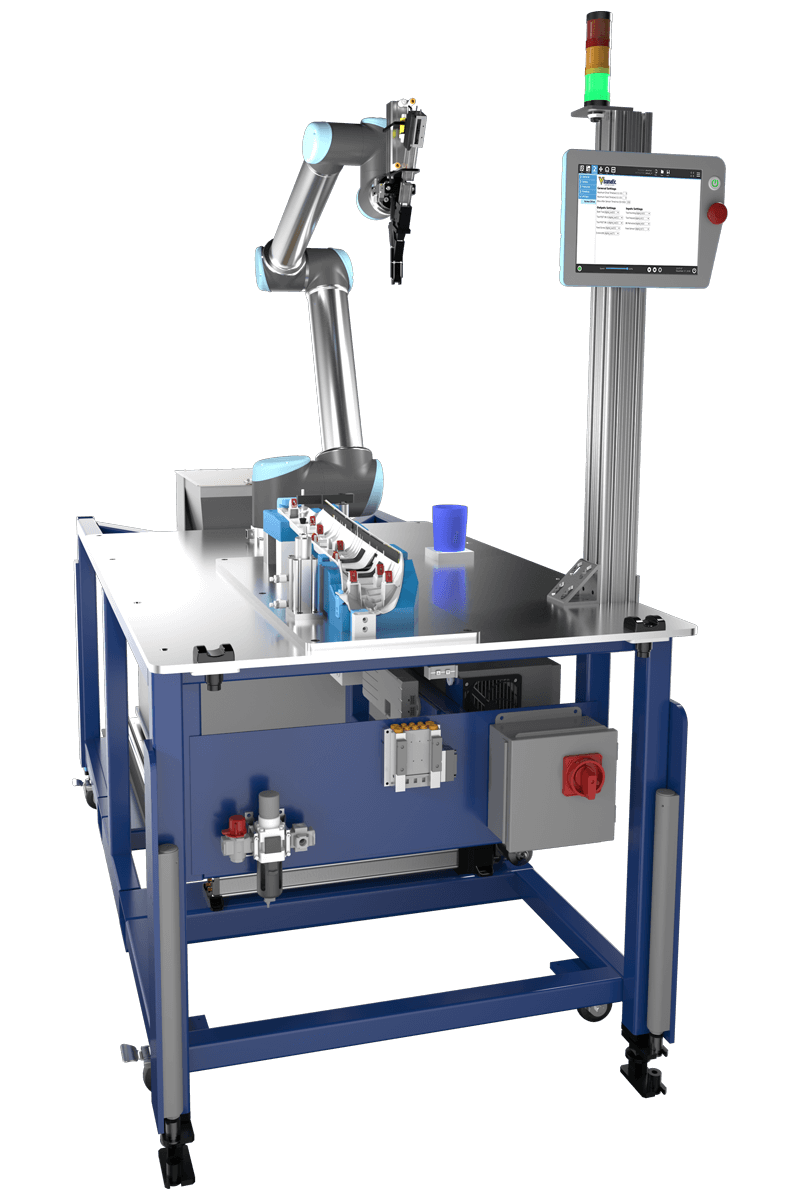

Cobot Clip Inserter

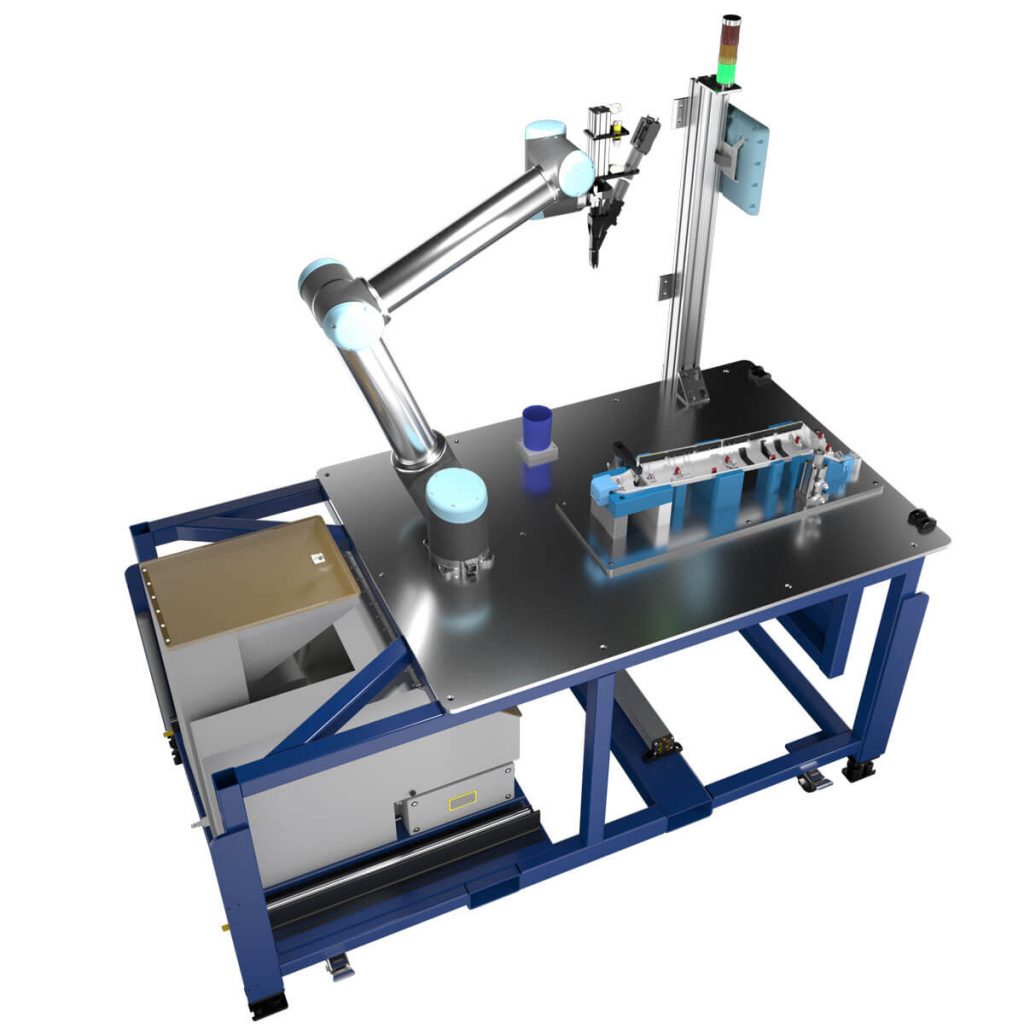

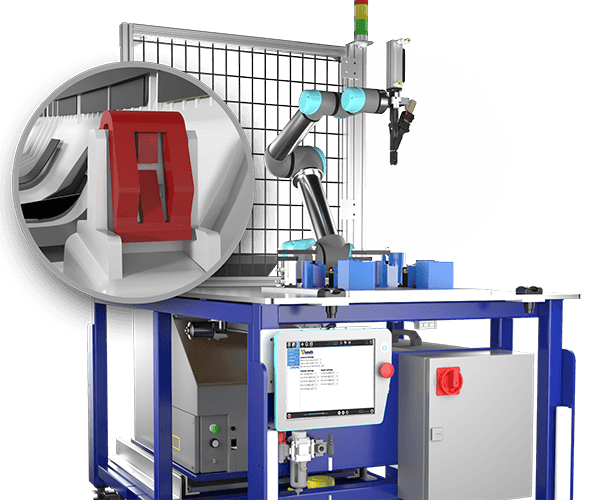

Application: Turnkey collaborative assembly workstation for repeatable cobot clip insertion.

Applying the right clip insertion gear can solve tedious ergonomic production challenges. Our cobot clip inserter workstation evolved as an automotive interior trim manufacturer started a more complete automation program. Their internal build group began moving towards a common machine platform built flexibly enough for global facility deployment. Visumatic joined their team to develop this next-generation assembly work cell.

The Visumatic Advant-edge

The right application of plug-and-work assembly technology that matches your process and productivity goals.

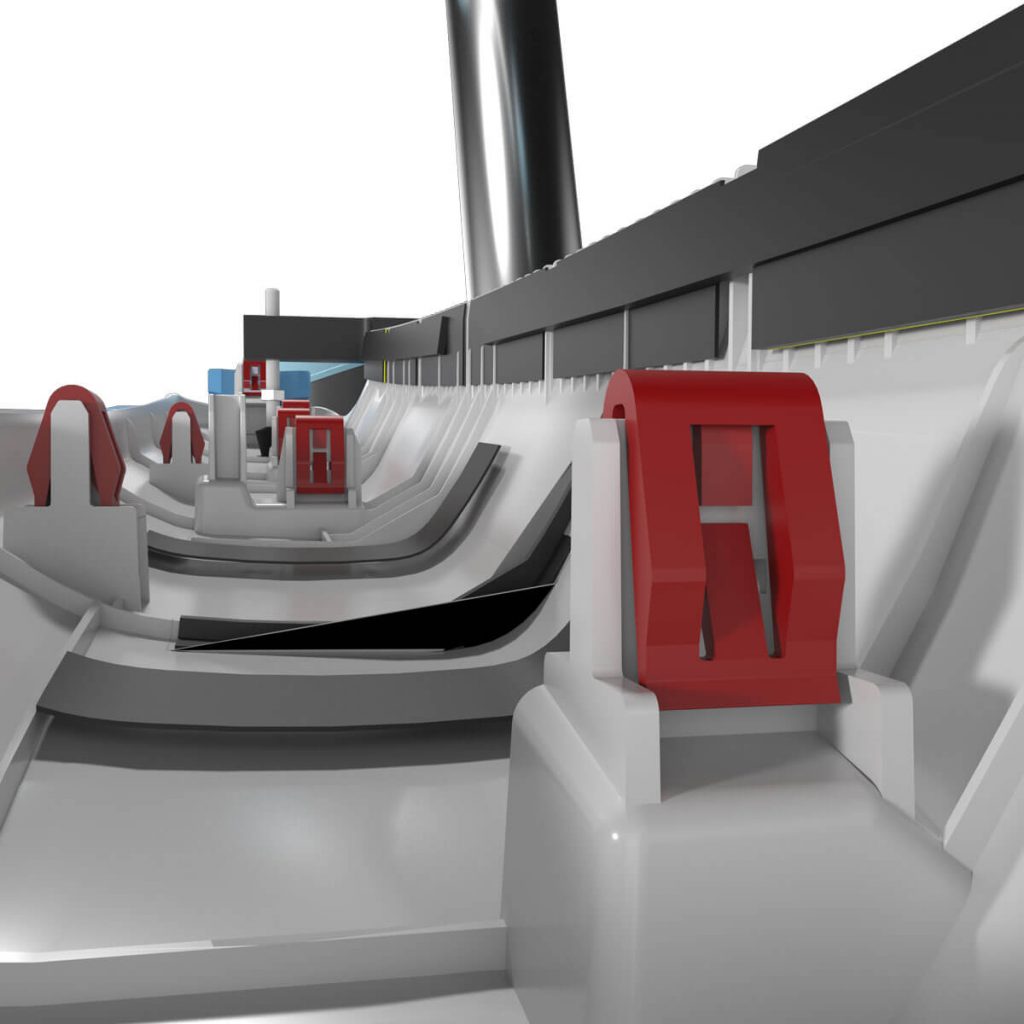

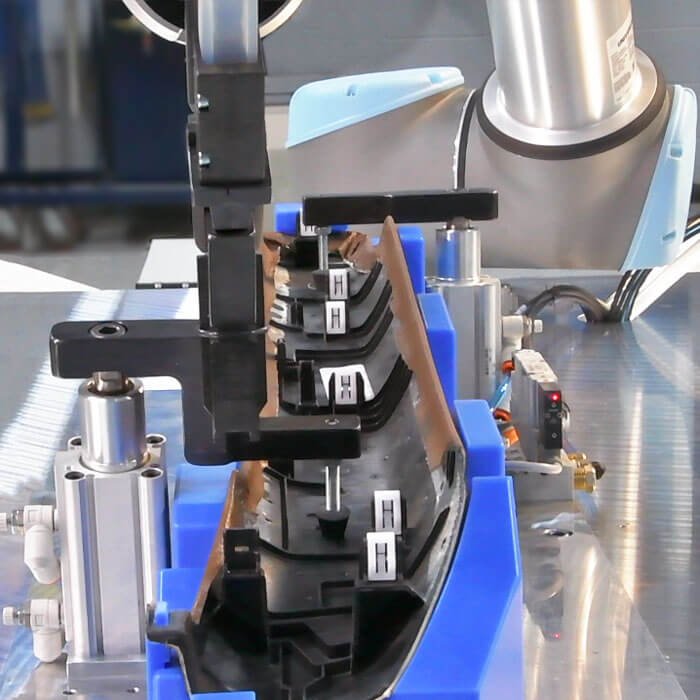

It combines a UR-10 collaborative robot with a Visumatic VIM-700 clip insertion and feeding system. The labor-saving gains are augmented with ergonomic advantages resulting from automatic clip handling. A built-in table surface height adjustment component allows the operator to work in optimal comfort. The cobot clip inserter cell includes a sensorized clamping part fixture and dual-hand opto-touch cycle start.

All sequencing is managed by the Universal Robot controller simplifying operation.

The machine installs the clips in a predetermined order, monitors proper insertion depth, and logs each successful insertion to qualify the assembly. This unique mix of technologies allowed the group to move beyond traditional robotic automation barriers without the burden of a specialized programmer.

Available Features:

- Smart Fixture senses part presence

- Light Tower system status indicator

- Clip feeder with bulk supply hopper

- 360 degree safety area scanning

- Push-button ergonomic table lift