VPA Ergonomic

VPA Ergonomic Tool Support Assist

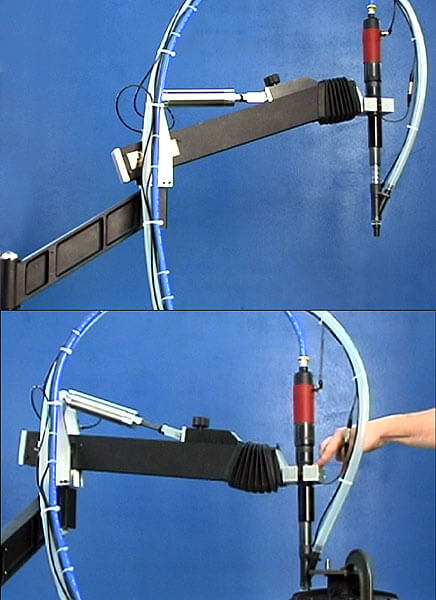

VPA Ergonomic system takes the screwdriver weight and torque reaction off operators to speed production. Powered option provides downward tapping force for low to extremely large high-torque assembly processes relieving repetitive muscle strain.

We understand operator challenges and ergonomic demands. With the torque/balance Power Assist Arm, Visumatic accomplishes a tremendous ergonomic and efficiency advantage while delivering a great value in labor asset protection.

Improves Ergonomics by reducing elbow stress, repetitive muscle fatigue & the possibility of carpal tunnel syndrome:

- Virtually eliminates torque reaction.

- Operators hand is closer to the work plane.

- Monitors and releases the drive-down force at a pre-determined value.

- Protect operators by applying the drive-down tapping force during assembly.

The Visumatic Advant-edge

Torque reaction arms are sized to fit your application and available standard or powered with safety release foot switch. Because after all, your employee is your best asset.

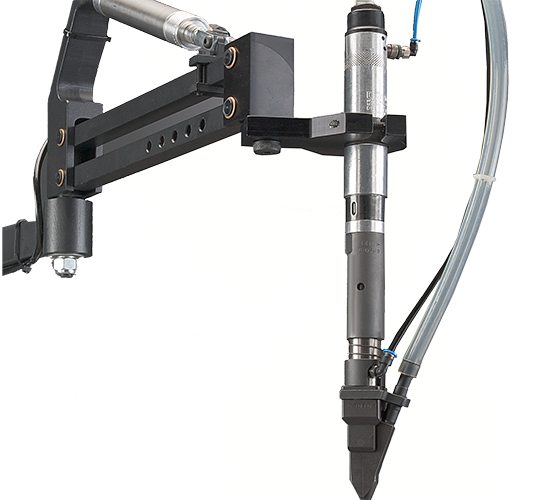

Visumatic Power Assist and standard ergonomic torque reaction systems are configured for your process, with the best choice of:

- Sized-Right Drive Motor: Pneumatic or DC Electric Torque Control

- Part Interface Tooling: Jaw, Fin-Jaw or Nut-Jaw

- Feeder Escapement: Standard or Custom

Field Proven. Operator Accepted.