6 Axis Cobot Workstation

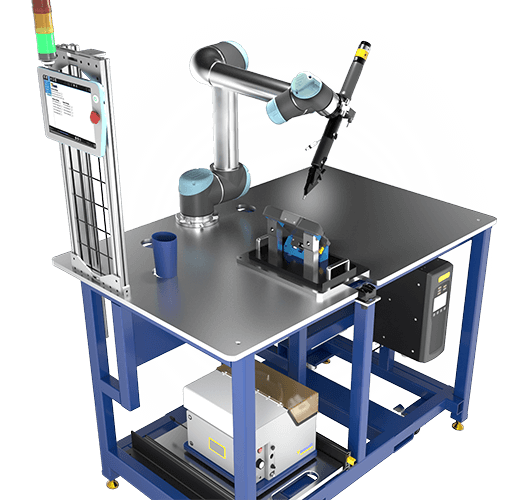

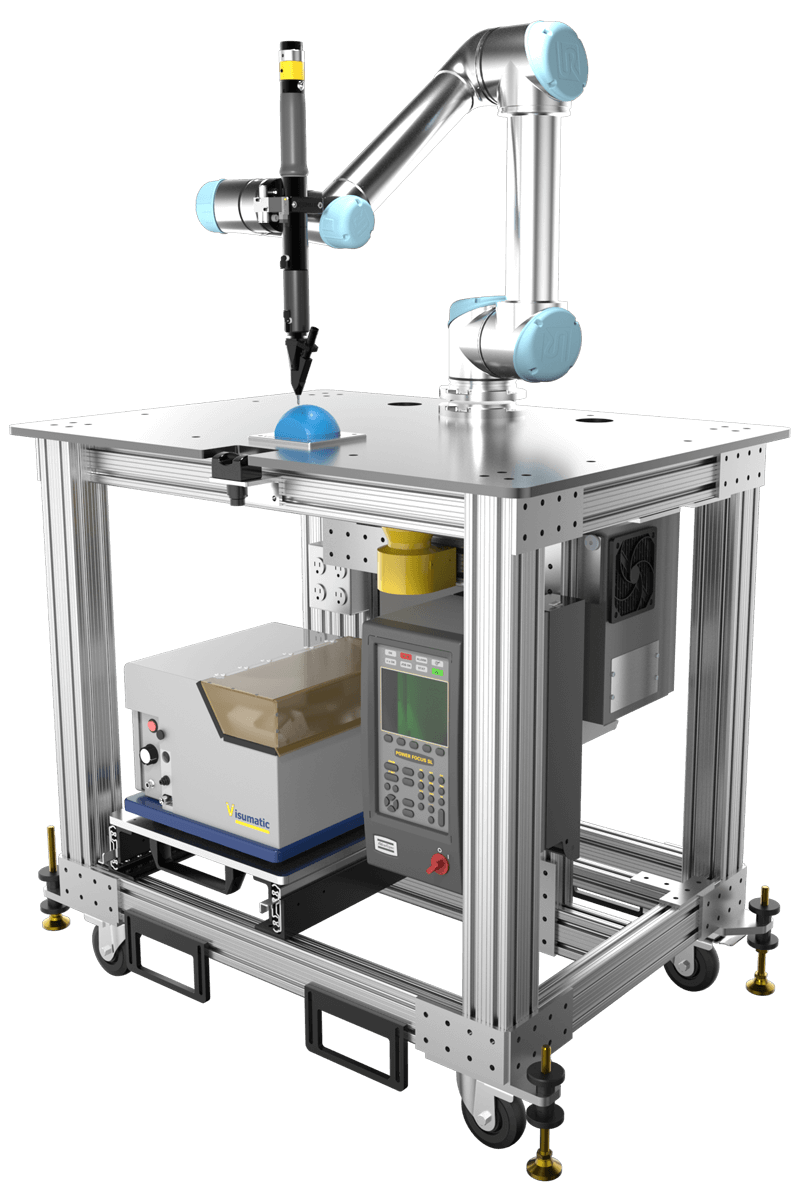

Application: Turnkey cobot screwdriving workstation built feature packed for flexible collaborative assembly.

Start a new chapter of fastening automation with Visumatic’s cobot workstation. This turnkey robotic screwdriving assembly cell has the flexibility to be implemented on an existing line or as a portable workstation. Complete cobot screwdriving package includes all the process control gear you need to get automation done.

The Visumatic Advant-edge

Quick start up with Visumatic’s plug and perform turnkey assembly cobot workstation.

This blend of technologies will move you beyond traditional robotic automation barriers without the burden of a specialized programmer. The six-axis robot has the agility required to handle parts with compound surfaces today and in the future. Our standard screwdriving configurations have the built-in capability to fit your process flow.

Visumatic’s cobot workstation hits your floor ready to go with these great features:

- UR5e Collaborative Robot / 850mm Reach / teach pendant

- VCM-3X.2 cobot screwdriver module with Model 94 feeder

- Torque/angle control tightening system

- Basic part fixture with manual clamping

- Visumatic standard workstation frame assembly

- Opti-Touch cycle start button

- Area scanner with 270 degree enhanced safety zones

The workstation comes fully programmed utilizing our certified URCap cobot screwdriving solution. It leverages Visumatic’s world class fastening experience to qualify your application. A simple yet powerful tool to allow your robot to perform real applied work.

Optional Features:

- Light Tower system status indicator

- Smart Fixture with part presence sensors

- Bulk fastener supply hopper with controls

- 360 degree area scanning

- Vision tasks and inspection

- Additional customizations available

The area scanner augments cobot safety protocols by creating defined workstation proximity zones. When personnel detection occurs in the intermediate zone, robot speeds are reduced. Robot movement is completely halted if the closet zone is reached.

Let the cobot screwdriving experts cut your implementation time and improve worker safety.

CASE STUDY

Cobot Workstation Jump Starts New Product Production

An electronics manufacturer was rolling out an updated product design and they wanted to prove out a new form of process automation at the same time.