Custom Feeder System

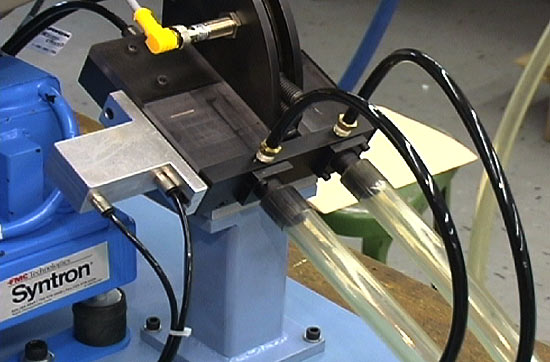

Application: Automatic feeders engineered to efficiently handle common screws to extremely difficult fasteners.

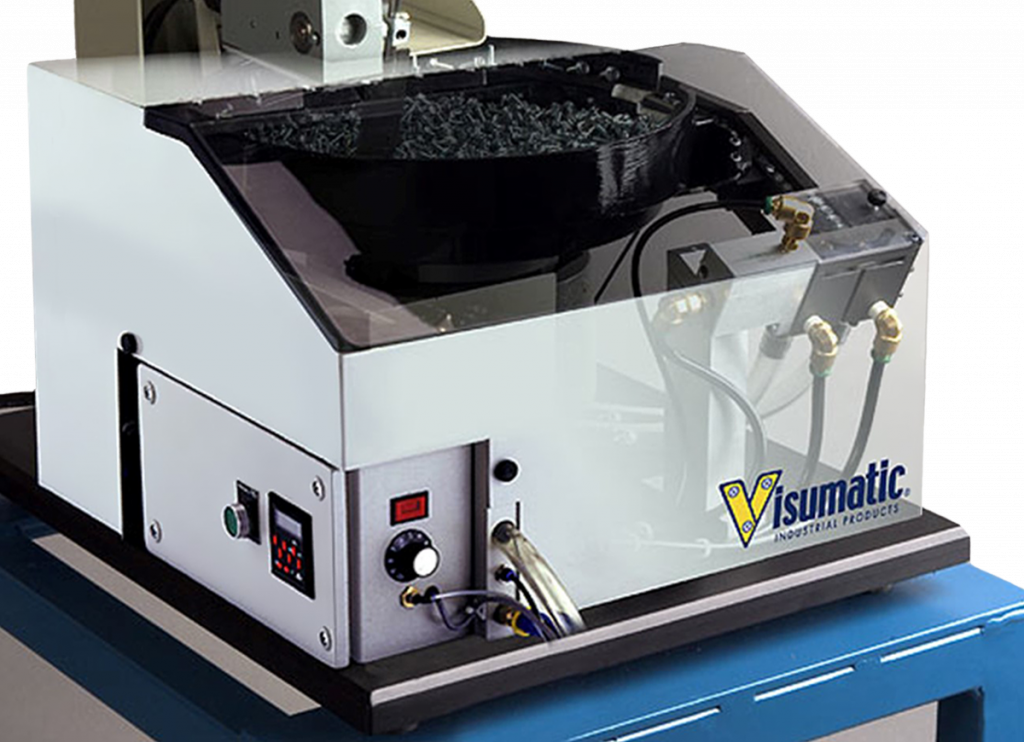

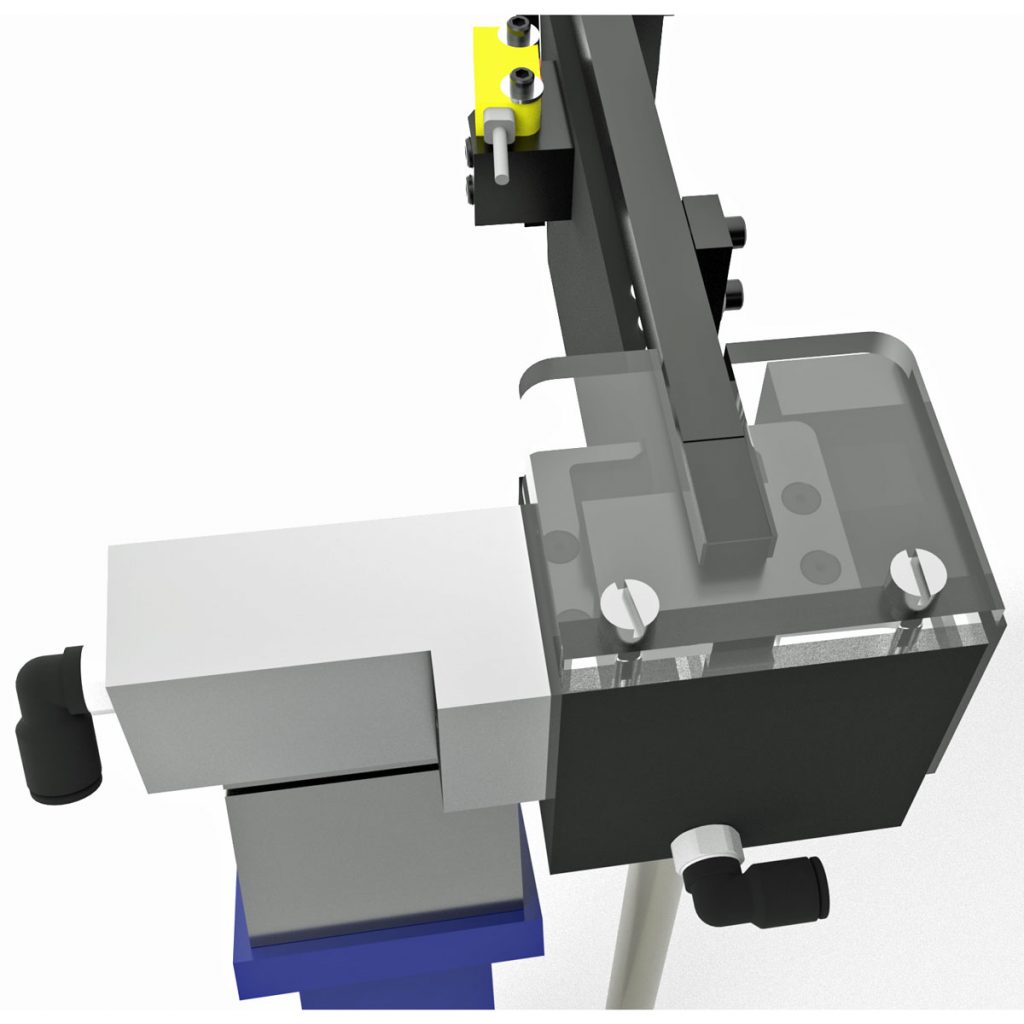

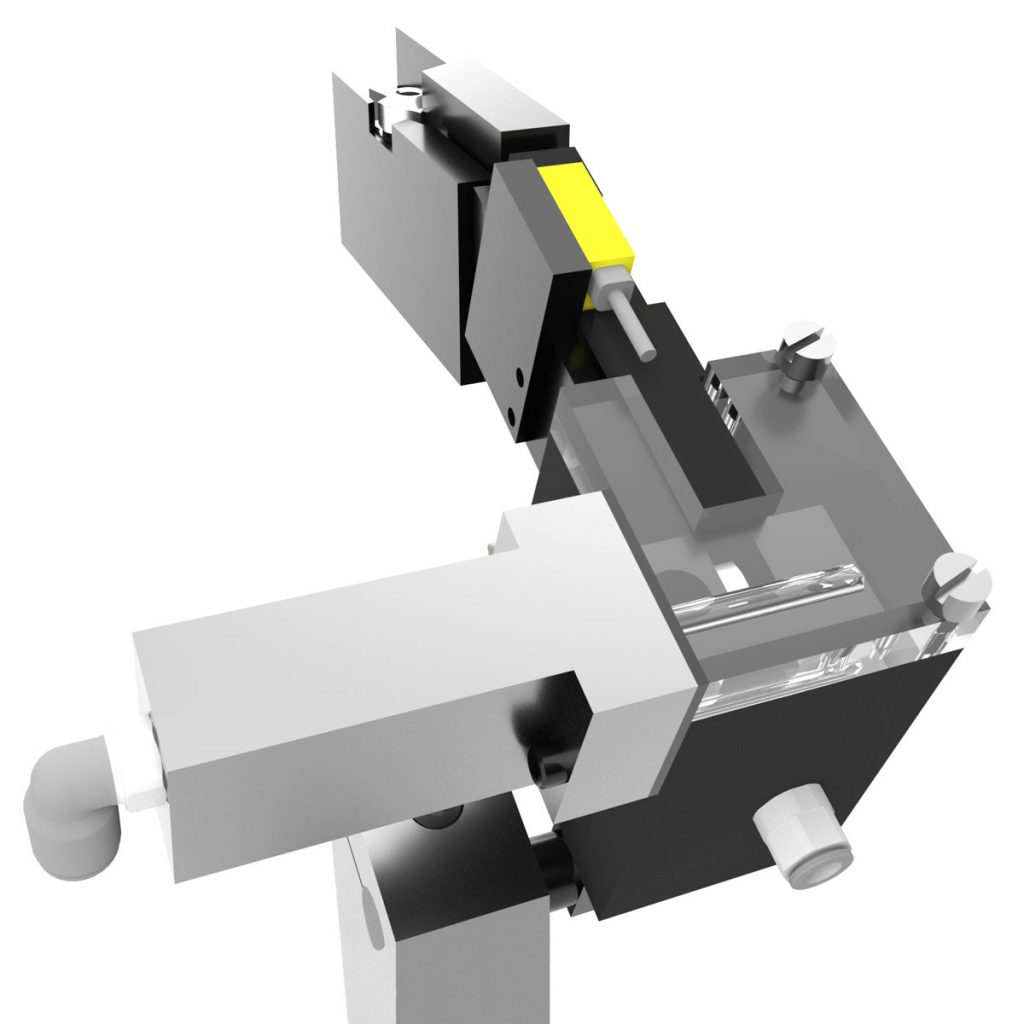

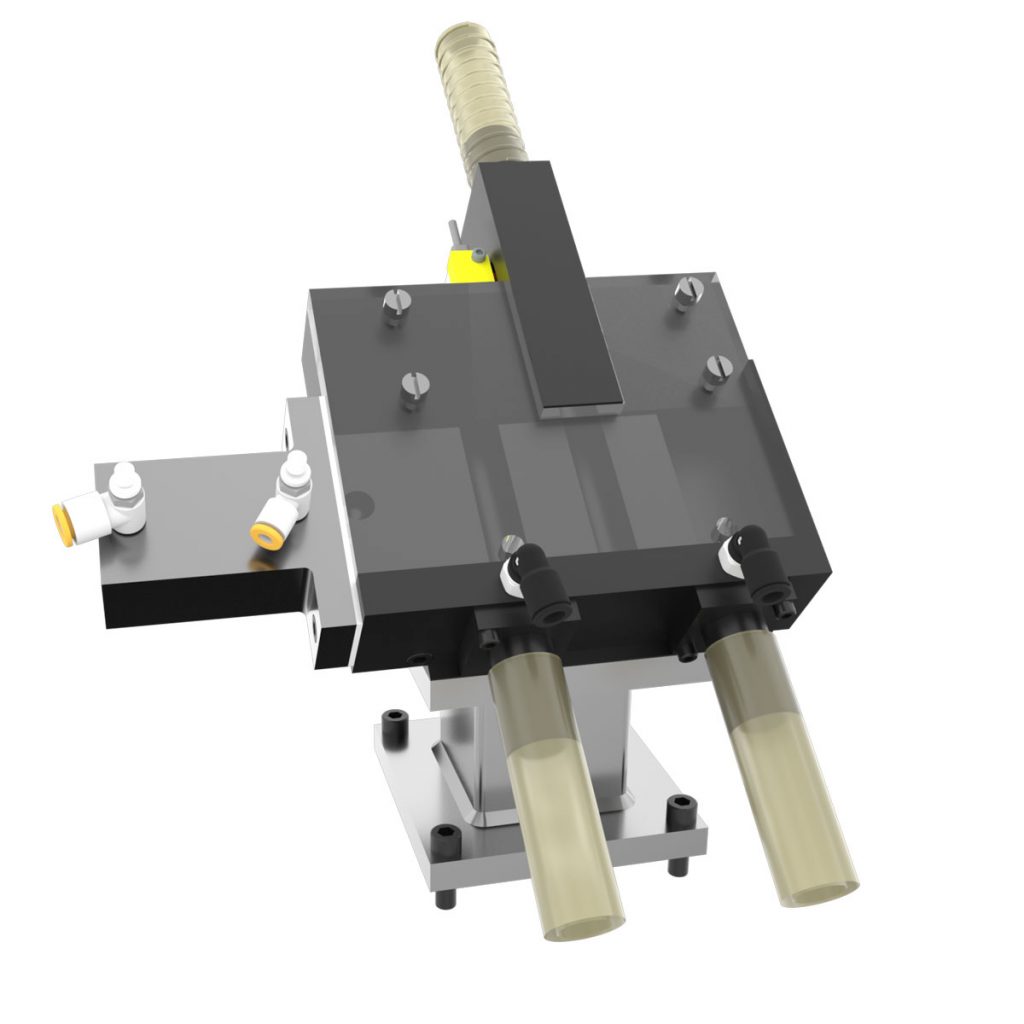

Visumatic Feeder Systems are simply the best on the market and set the industry standard. Our feeders are 100% designed and built in-house, utilizing escapement designs that fit your specific application requirements. All our escapements deliver the highest possible value because there are no external springs to fatigue and the fewest moving parts in the industry.

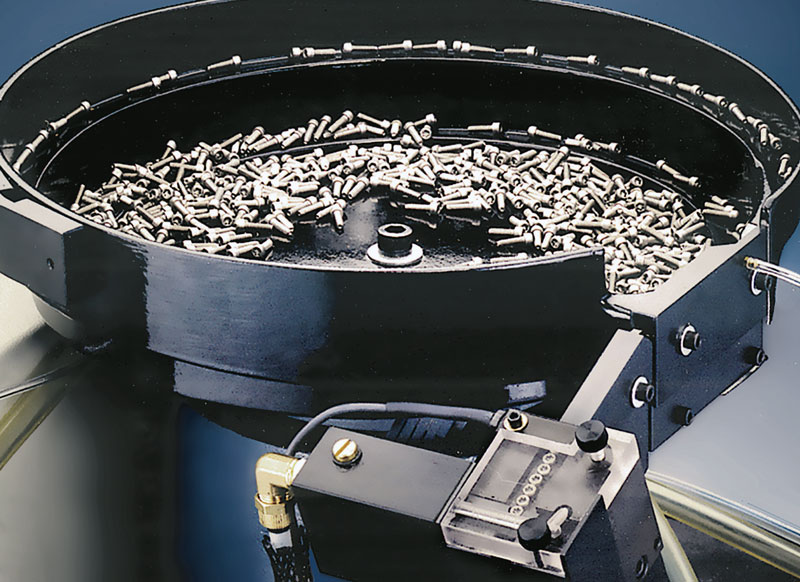

A sensor in the bowl signals the hopper to dispense fasteners when the low-level limit is reached, keeping the bowl at the optimum level of fasteners, leading to longer bowl life and more efficient feeding.

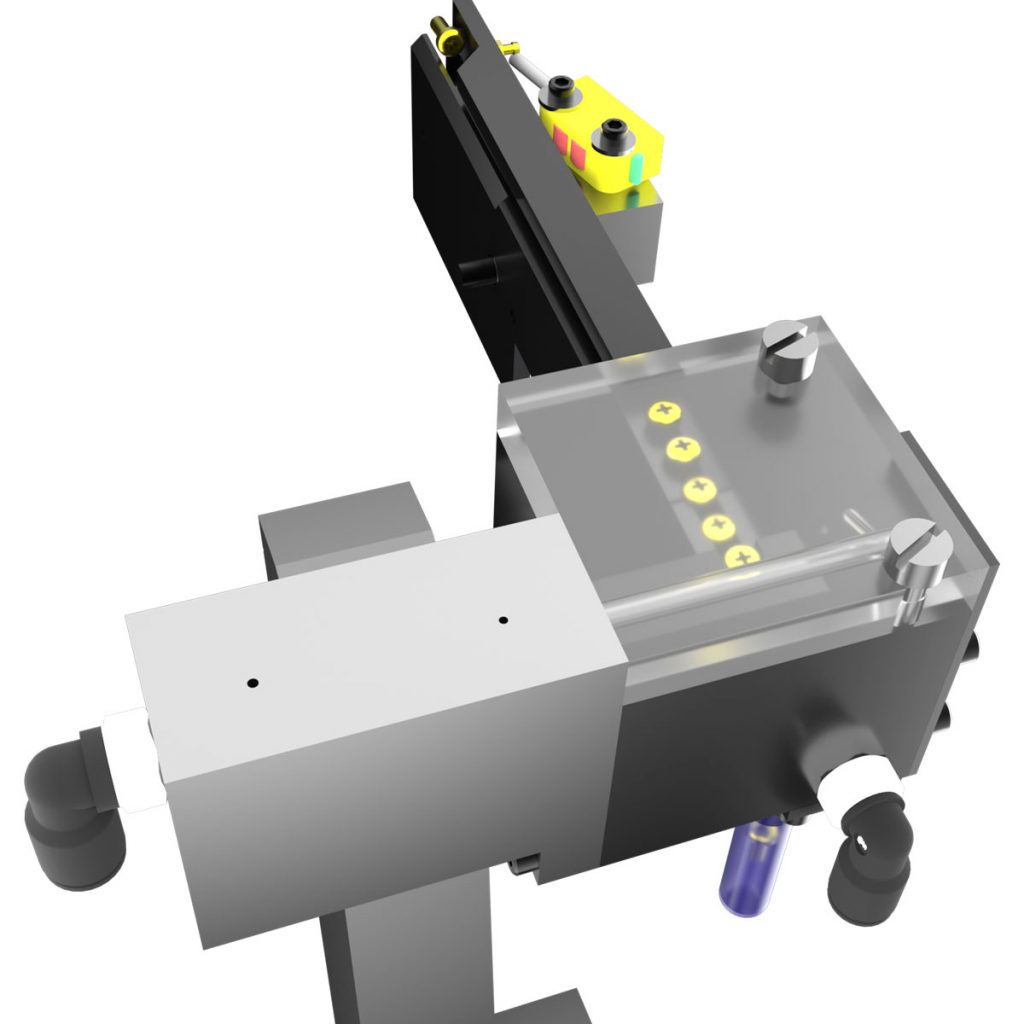

Visumatic has developed a series of exclusive feeder escapement designs, to handle:

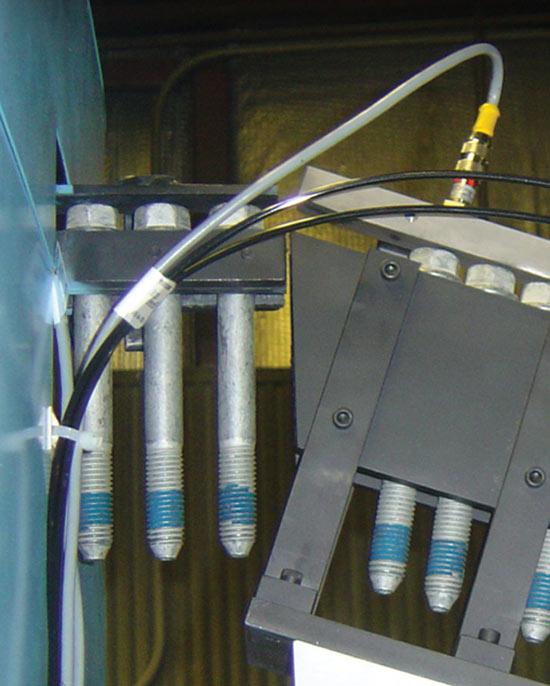

- Difficult to manage and place fasteners

- Run of the mill screws, nut, bolts, rivets, pins and studs

- Extreme sizes – very long, very short, very small

The range of feeder designs available guarantees Visumatic can accommodate your part and any fastener you will need to install today and in the future.

The Visuatic Advant-edge

- Simple – with one moving mechanism

- Engineered to match your fastener

Escapements are designed for your requirements in these standard configurations:

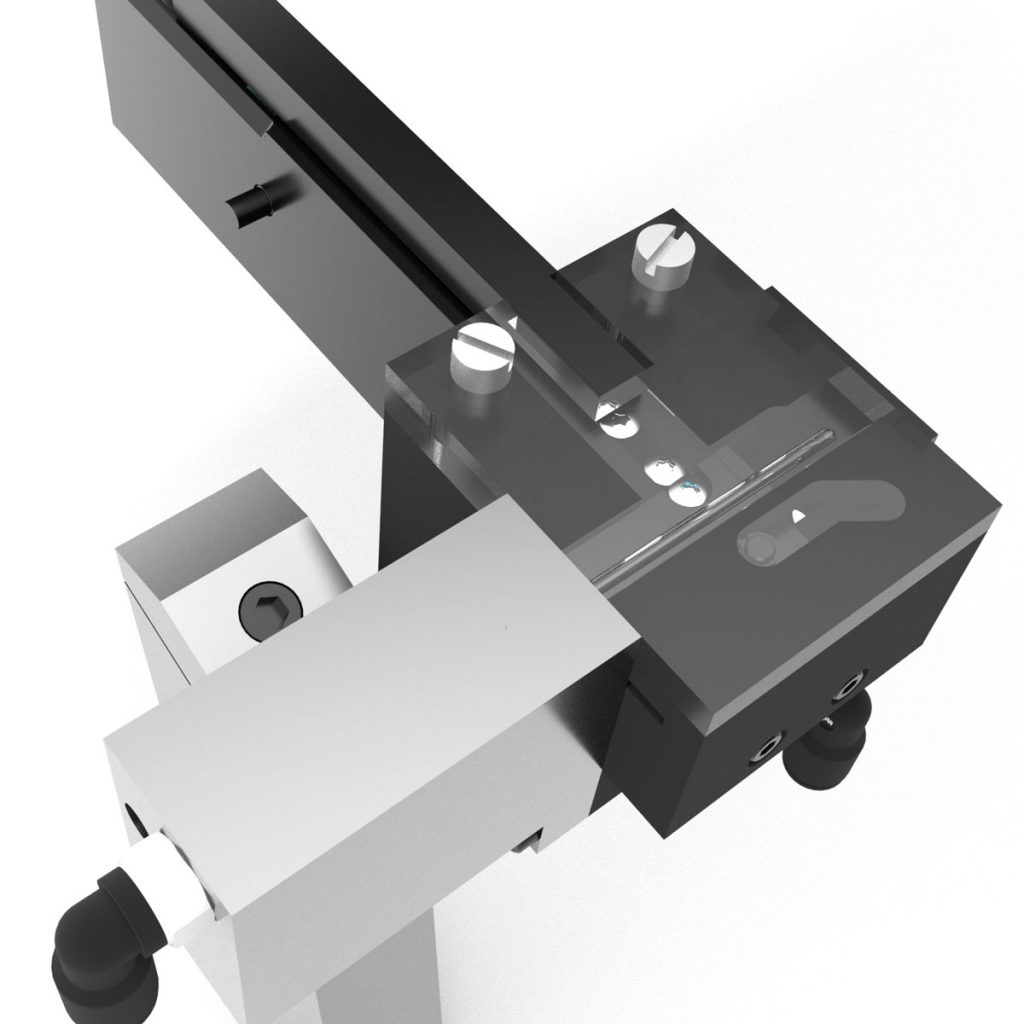

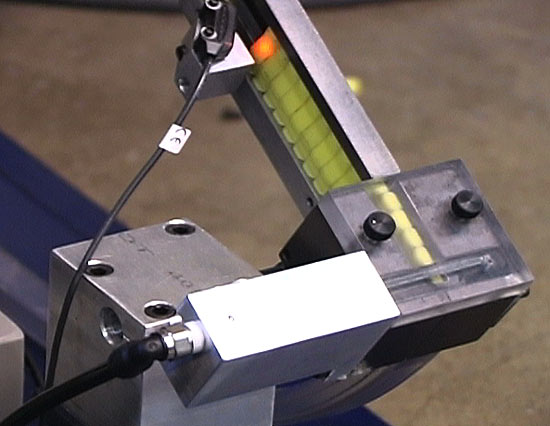

M-15 Standard Screw Escapement

C-15 Cam Escapement

F-15 Finger Escapement

N-20 Nut Escapement

S-18 Siamese Escapement (Full Automation Only)

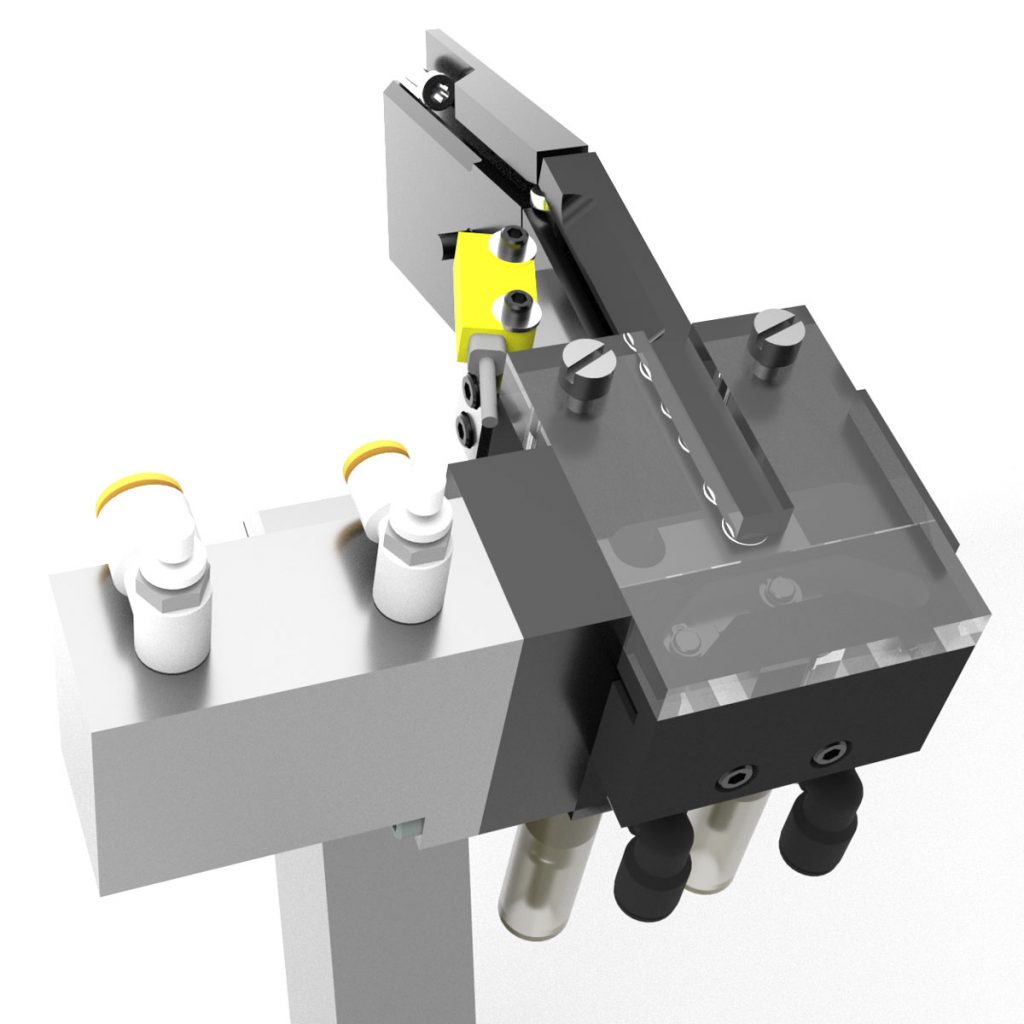

Every feeder system come with automatic feeder bowl shut-off for low power consumption, and high flow valves with long blow distances for flexible feeder placement. The included board-level controller maintains the optimum level of fasteners, sequences the feed cycle, and provides adjustability for local environmental conditions

Microprocessor feeder controls are readily serviceable:

- On-board system status/diagnostics

- Surge protection

- Empty bowl alarm relay

- Automatic and remote feed signal

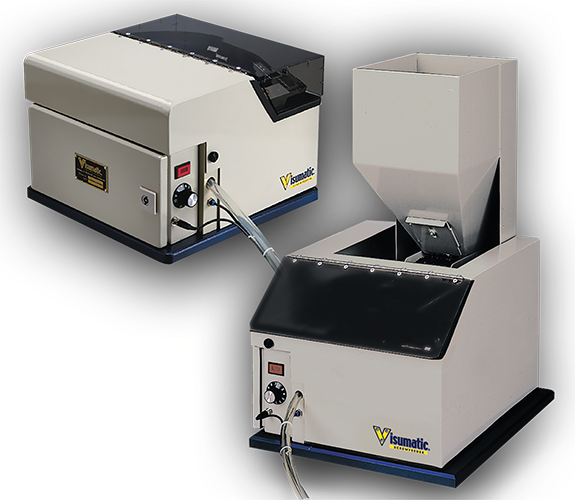

Optional Bulk Supply Hoppers:

- Can handle a gross box of fasteners (30-40 lbs)

- Operator adds screws 80% less often!

All custom feeders come complete with a durable steel sound-dampening enclosure that protects from dirt and foreign debris while making the workspace cleaner and safer.

A variety of vibratory bowls to suit your application requirements:

- Stock stainless steel

- Coated cast aluminum

- Custom fabricated stainless

Engineered Custom Escapements

Clip Escapement

Wooden Dowel Escapement

Large Part Escapement

Siamese Pinbolt