High Volume Screwdriving

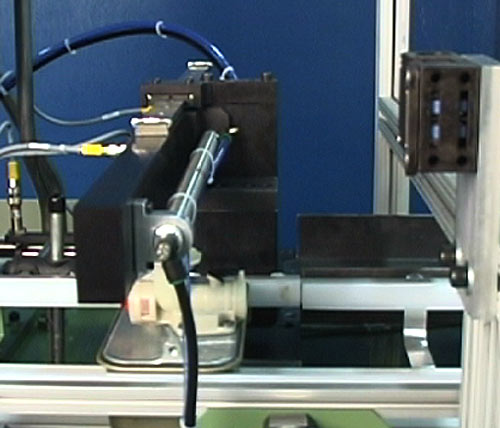

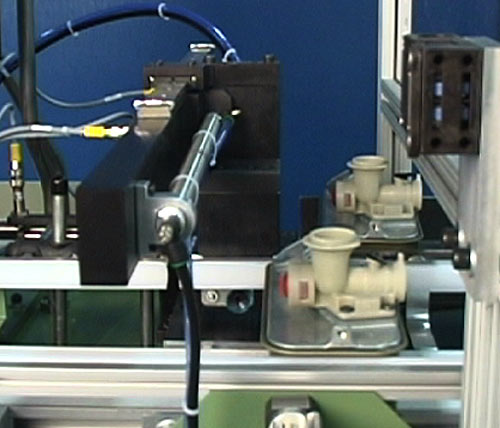

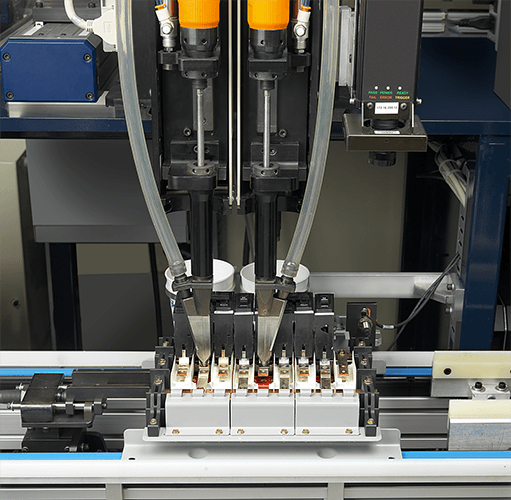

Application: Fully automated high volume screwdriving assembly equipment for rapid output production.

Visumatic can answer extreme fastening challenges from our customers, even when it means inventing new fastening technology. Subassemblies can be operator or machine loaded with the parts transferred through each step of the assembly process.

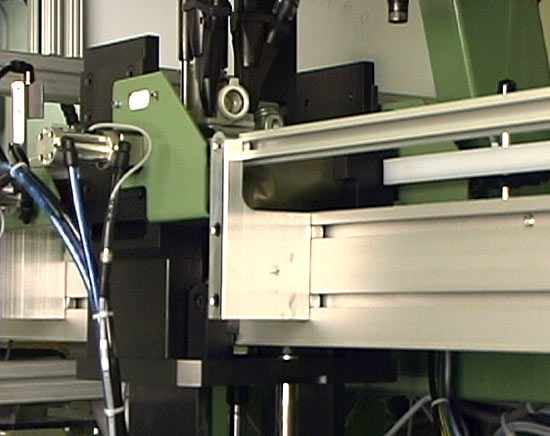

This high volume screwdriving approach used operators to pre-load the components while building up subassemblies progressively. The part is automatically transferred to the fully automated, multi-spindle screw driving stations for simultaneous driving. Finished assemblies are conveyed to an accumulation area for packaging.

The Visumatic Advant-edge

The right application of assembly technology that match your process and productivity goals.

Automating this multi-operator assembly process resulted in a reduced 1.5 operator head count per shift while production capacity increased by 40%. Quality assurance was enhanced through proper application of SPC techniques, also resulting in lower rejects/rework.

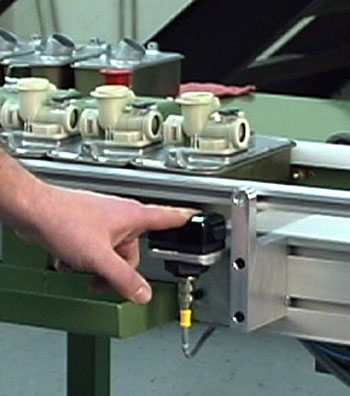

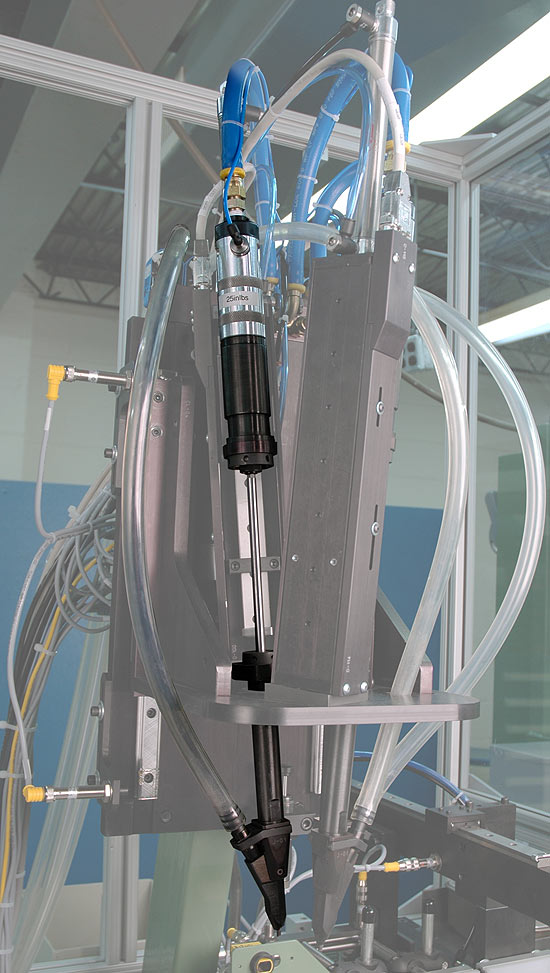

Visumatic high volume screwdriving machines are configured for your process, with the best choice of:

- Screwdriving Motor: Pneumatic or Torque/Angle Control

- Nosepiece: Fin-Jaw or Standard

- Escapement: Standard, Cam, Siamese, or Finger