Qualified Assembly

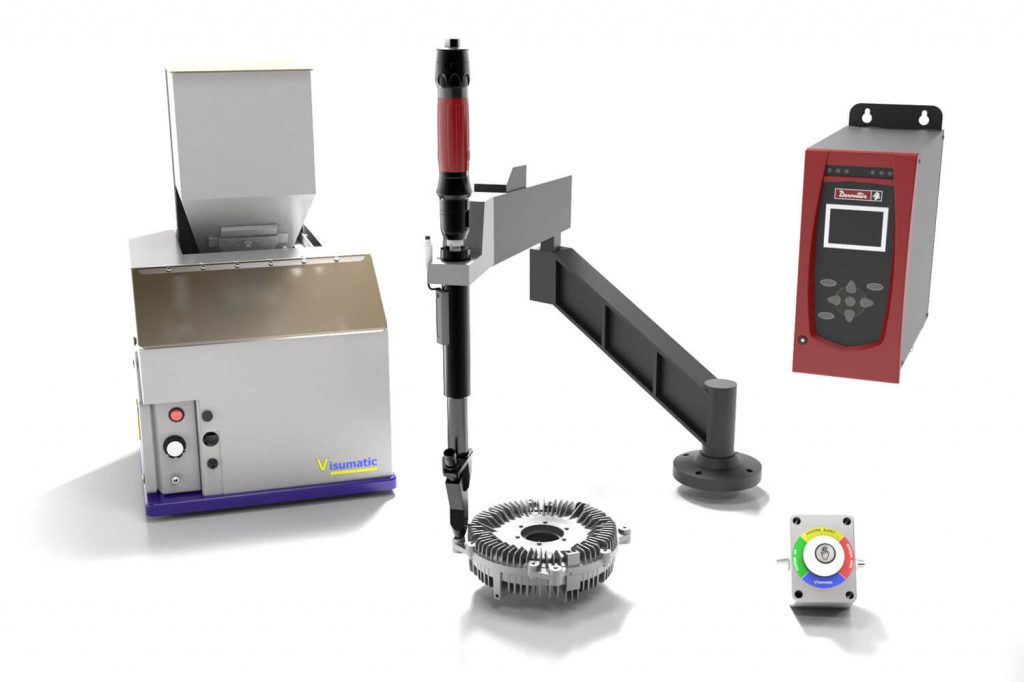

Visumatic helps you ensure a quality assembly by closing the gap between the automatic feeder and the screwdriver controller systems. The Qualified Assembly delivers basic screw auditing of your joining process without the need for complex programming.

The qualified feed sequencer monitors the output from the DC screwdriver controller, only signaling for the next screw to feed after an O.K. output is received. When a run-down problem occurs, the control interrupts the assembly process, improving part quality by requiring intervention. The system forces the operator to acknowledge the exception by pressing the control button and then automatically delivers the next screw to the nosepiece.

This configuration will also prevent the automatic feed of a bonus screw when a process error occurs. If the operator disengages the drive system mid-cycle, the next screw will not be fed, and the system requires a button push to continue processing the part.

The applied technology provides:

- Screw rundown data collection and reporting

- Additional quality pre-screening reducing rework and liability exposure

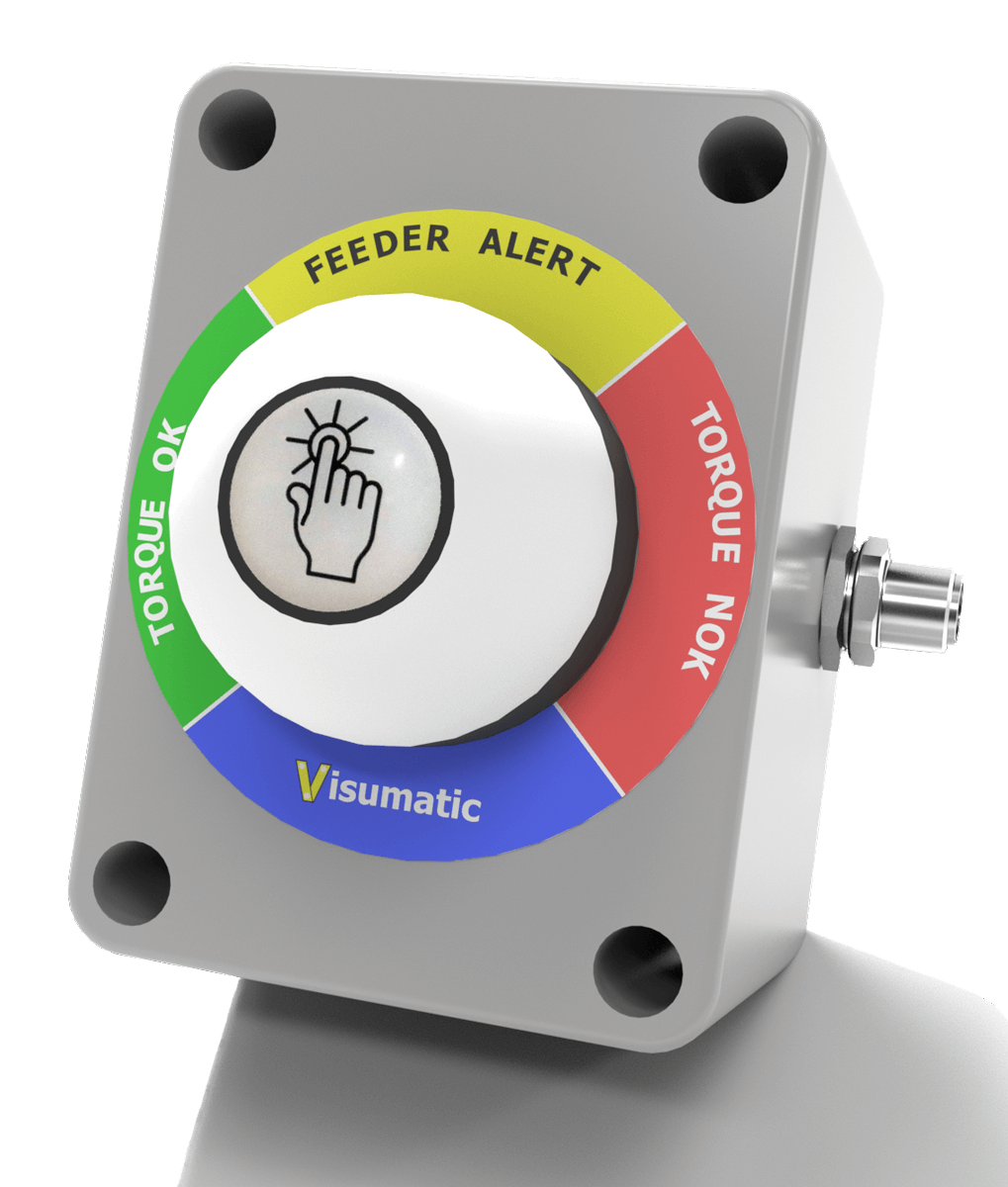

- Eliminates dropped or bonus screws. Illuminated Feed Screw button indicates system status by color output.

When advanced automation is not possible, the qualified feed platform acts as an additional process quality check to assist in part integrity and operator conditioning. The Qualified Feed control box delivers visual real-time system status indicating screw rundown good, a failed drive, and alerts the operator when the feeder fastener supply level is low.

The qualified feed collaborates with any controller helping ensure full SPC screw rundown data collection.

Visumatic can integrate any brand torque and angle control screwdriver into the system. If it fits the application, we have a system engineered to fit your motor.

The Visumatic Advant-Edge

- Forward-thinking design places the operator’s hand closer to the work for greater accuracy, efficiency, and control.

- Improved ergonomics eliminates operator squeeze actuating the screwdriver.

- Converts lever-start or fixtured tools to easy push to start.

Our system gives you the freedom to continue using the motor already accepted in your plant.

Your Process. Our Commitment.