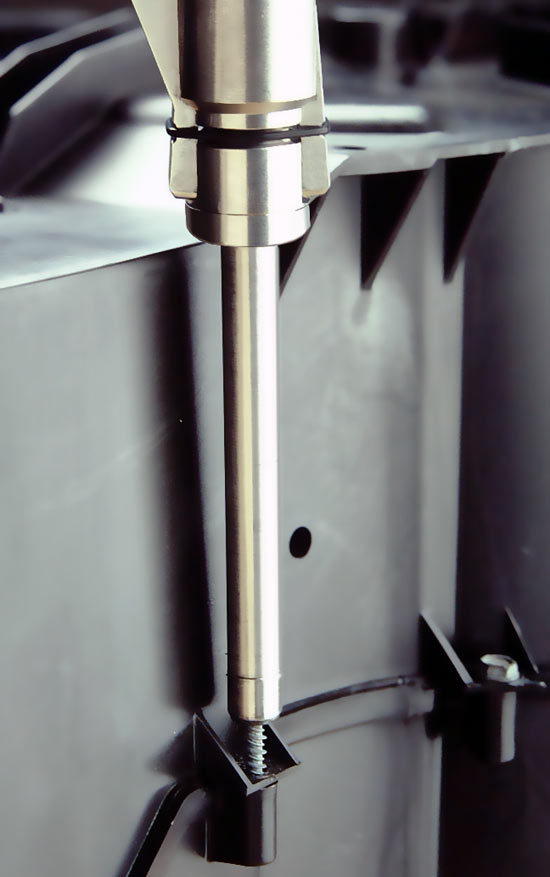

VEB-900 Extension Bit

Easy Access. Extended Bit. Built Better.

Application: Installs fasteners in hard to reach spaces and complex part geometry.

Visumatic invented the VEB-900 Extension Bit nosepiece to automate assembly when the part has drive locations each with a unique and tight clearance. The VEB-900 works by accepting the fastener in the main body of the nosepiece and automatically extending the fastener into the proper driving position.

The Extension Bit is the right choice for your assembly process:

- Where access to the driving location is limited to the fastener and bit only

- Where the extension of the fastener outside a set of jaws is needed for tight clearance or tall surface features

The Visumatic Advant-edge

- Extends the fastener outside the nosepiece tooling tip

- Operators use the fastener to engage the hole prior to initiating the drive

- No flexing of the wrist or jamming the nosepiece against the part

- The tooling tip is designed to fit your unique part and your application

Visumatic VEB-900 Extension Bit auto-feed and drive systems are engineered for your toughest application with the right choice of:

- Drive Motor: Pneumatic, AC or DC Electric Torque Control

- Nosepiece: Jaw, Mini-Jaw, or Nut-Jaw

- Feeder Escapement: Standard, Cam, Nut, or Finger