VLB-900 with Finder Tip

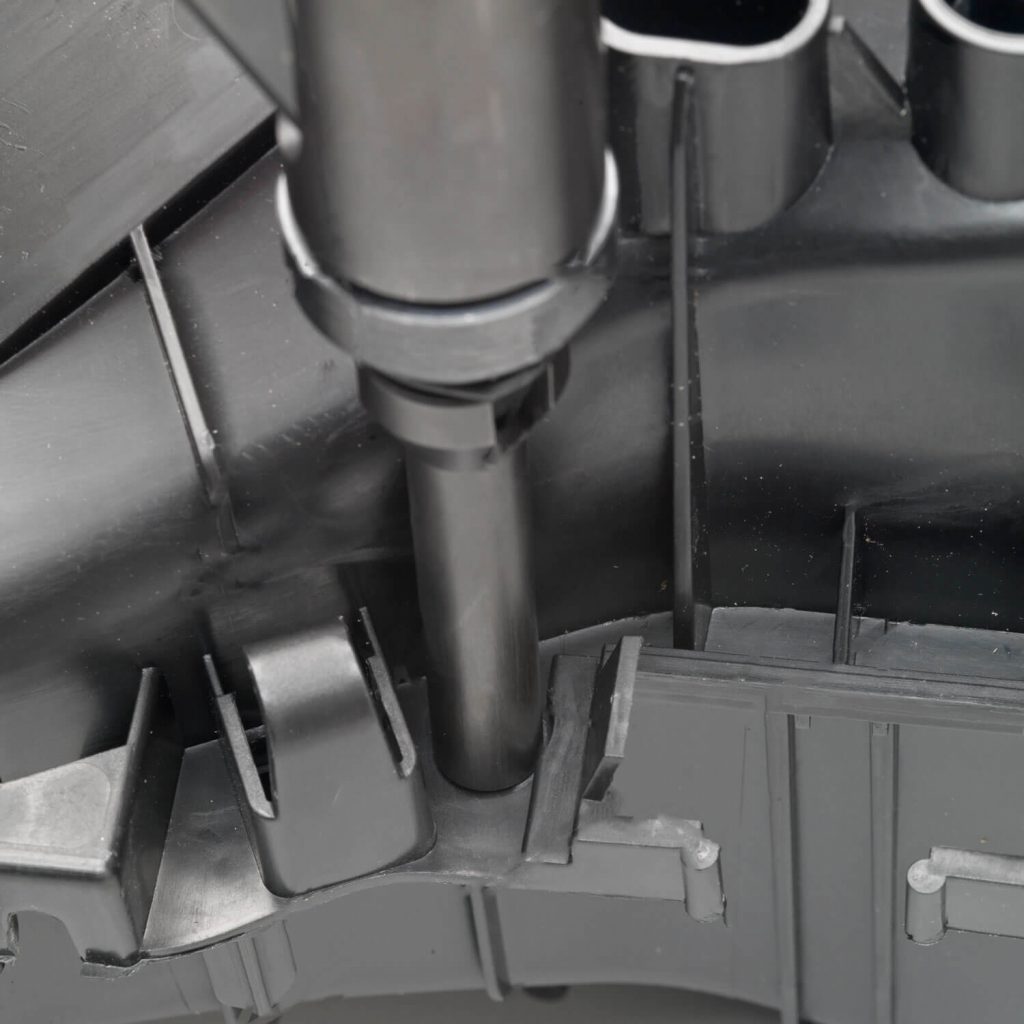

Visumatic’s Fin-Jaw nosepieces are ergonomically designed to make driving easier for the operator. Tooling tips are engineered to provide positive engagement between the components and automatic screwdriver.

The operator can easily see and feel correct placement, even on blind holes and counterbores. Finder Nosepieces are engineered to fit your part, clearing irregular surface details while controlling the screw.

Combined with the Model 94 Automatic Feeder, the VLB-900 with Finder Tip will boost productivity by rapidly installing screws in blind holes, counterbores, and against tall surface features.

The Visumatic Advant-edge

- Advanced Microprocessor controls

- Lever, Trigger or Push-to-start

- Delivered complete with the simplest, most reliable feed system available.

- One Movement, Zero Adjustments

- Extremely quiet steel enclosure eliminates debris

- Longest blow distance on the market

- Greater control and capability

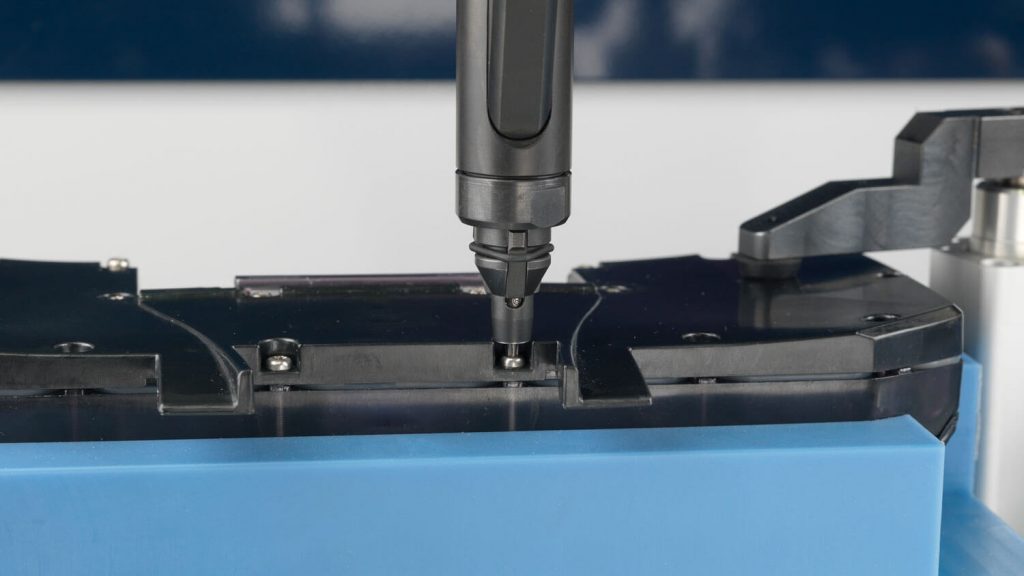

Fin-Jaw tooling tips can also be applied in fixtured screwdriving systems.

VLB-900 Finder Tip systems are designed for your part, with the best choice of:

- Drive Motor: Pneumatic, AC or DC Torque Control Systems

- Feeder Escapement: Standard, Nut, Cam, or Finger

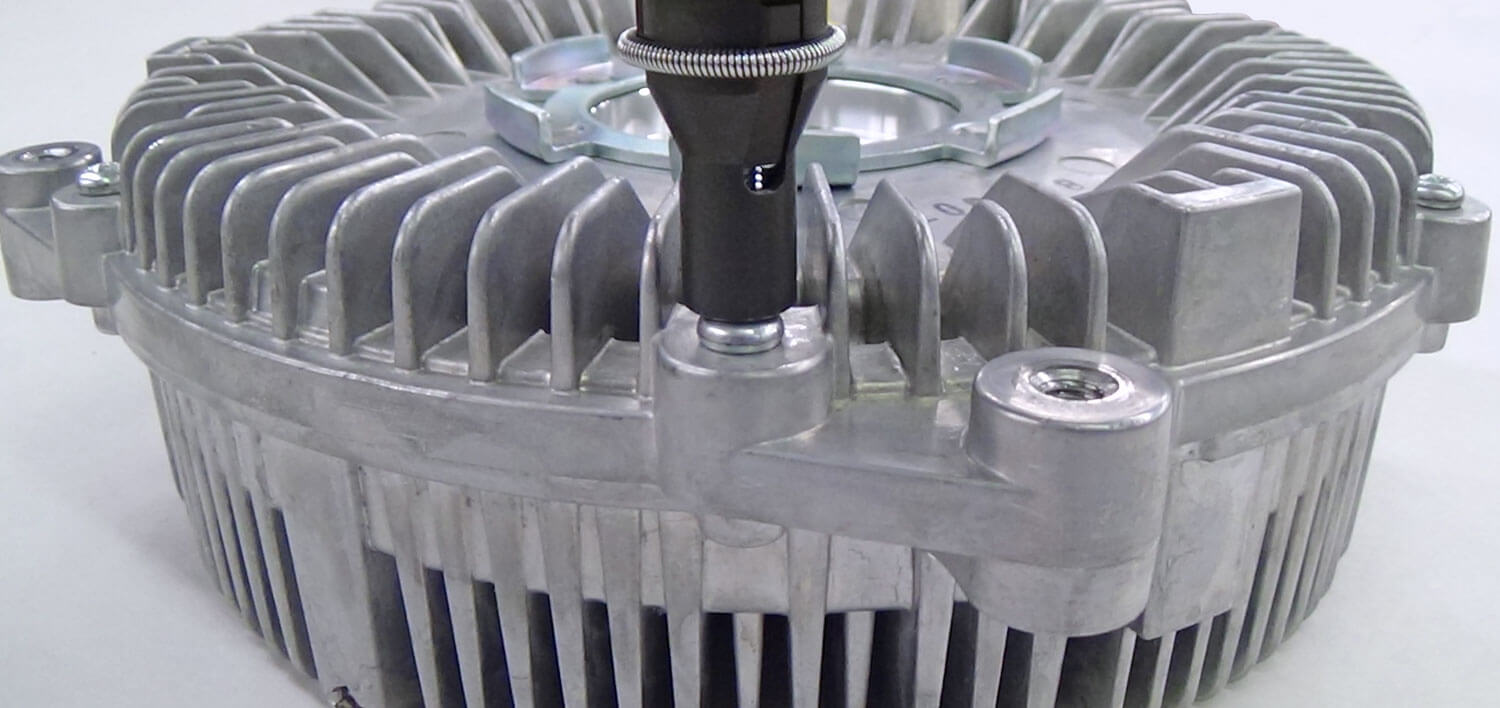

CASE STUDY

Application Spotlight ~ Higher Torque Screws Installed in Tight Spots

Assembly Process: Automatically feed and drive, one per cycle, an M4 x 20mm long torx drive pan head screw to required 4.8 Nm torque to secure a fan clutch housing. A radial torque arm was required to absorb the tightening reaction forces and also assist the operator with vertical alignment.