VZP-900 Zero Push

VZP-900 Extension Bit Screwfeeder

Let the machine go through the motions for the operator.

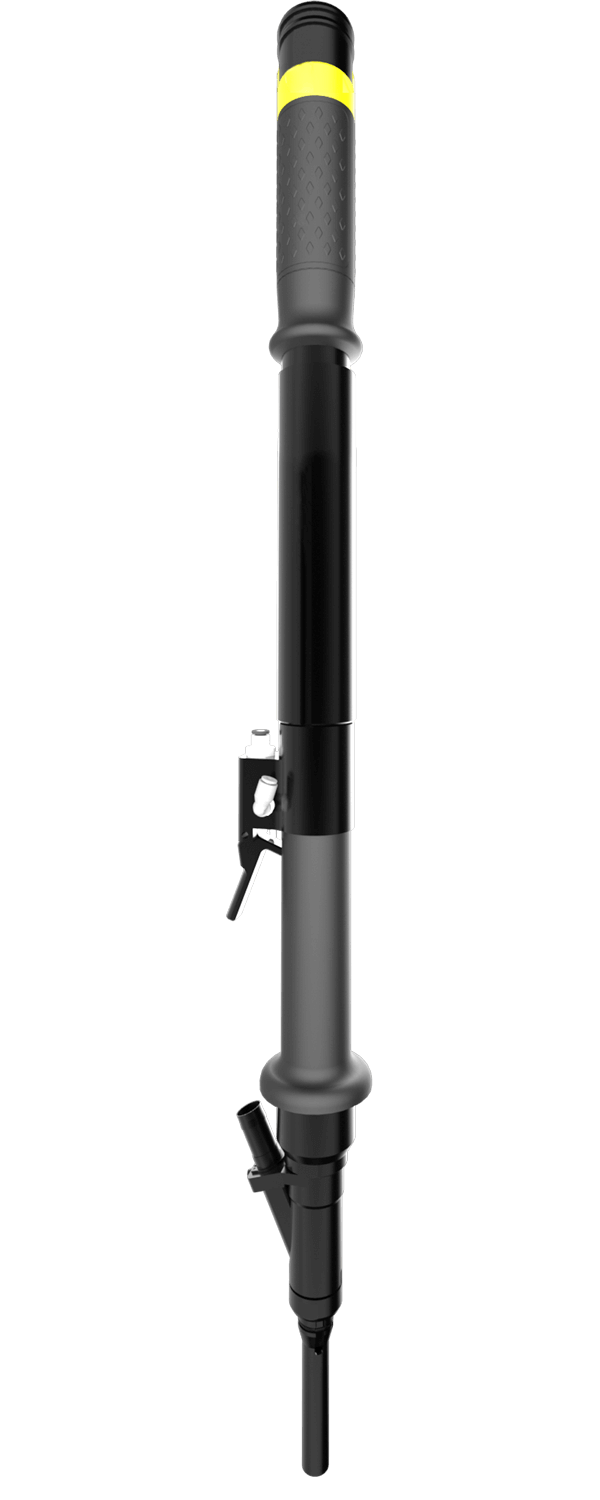

Visumatic’s Zero Push screwfeeder is the top of the line of handheld automatic screwdrivers, improving operator productivity and acceptance. The VZP works when you have clearance issues or deep recesses where conventional nosepiece tooling won’t work. It requires only a light trigger touch to install the screw.

Operator engages the hole before the drive process with:

- No flexing of the wrist

- No forcing or jamming the nosepiece

- Virtually no Z-axis motion

Visumatic Zero Push delivers ergonomic and productivity benefits:

- Far superior feel of the assembly in the hand

- The operator positively locates drive position prior to initiation

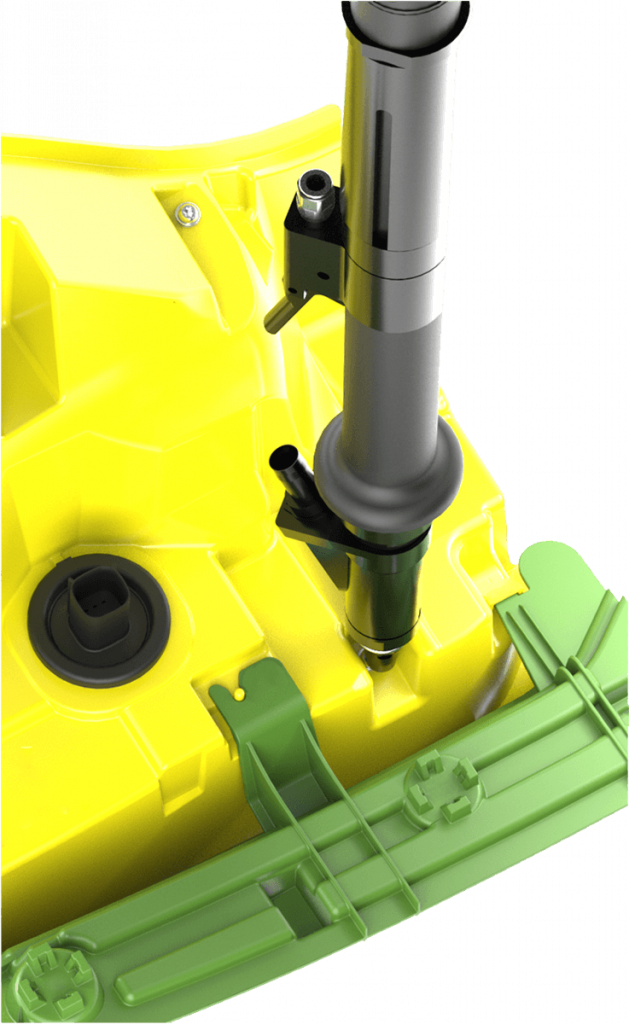

- Great for tough to handle limited access applications

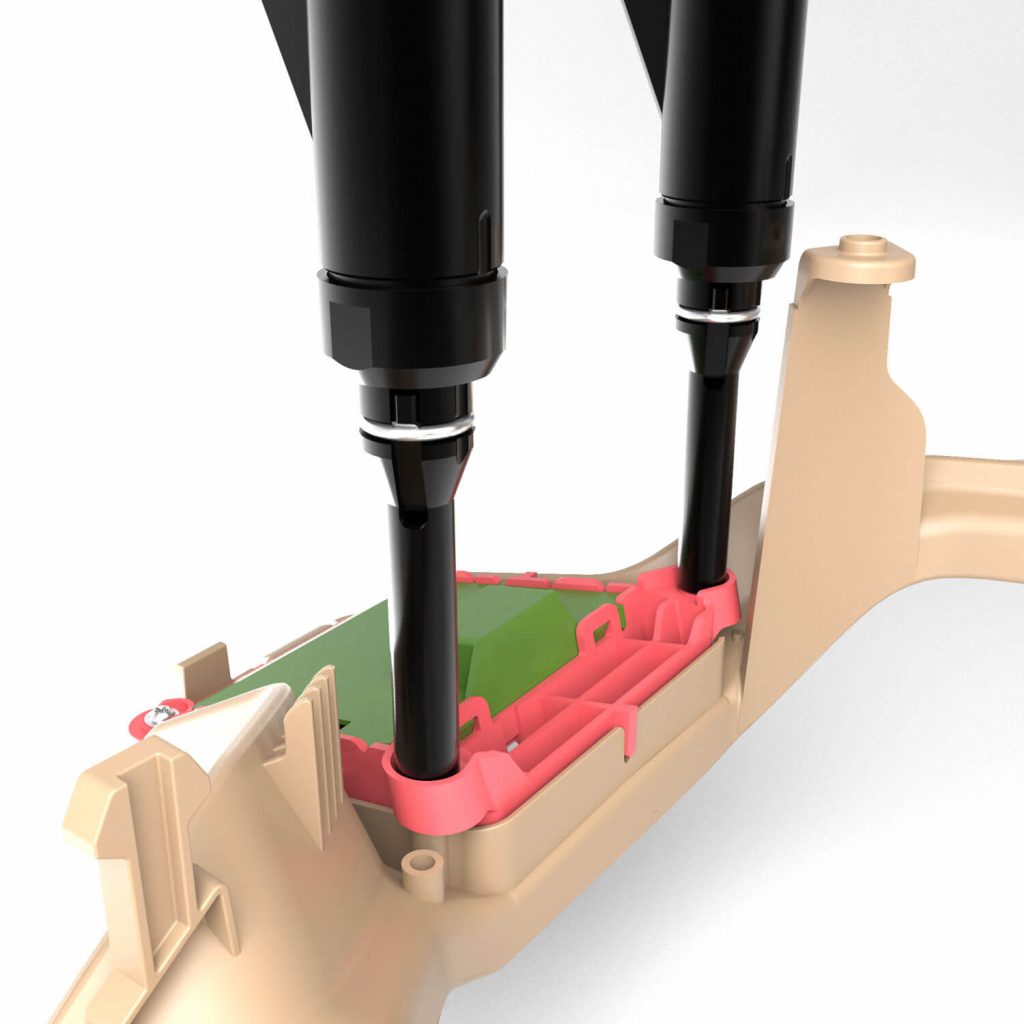

- Designed for multiple drive locations, with unique or tight clearance

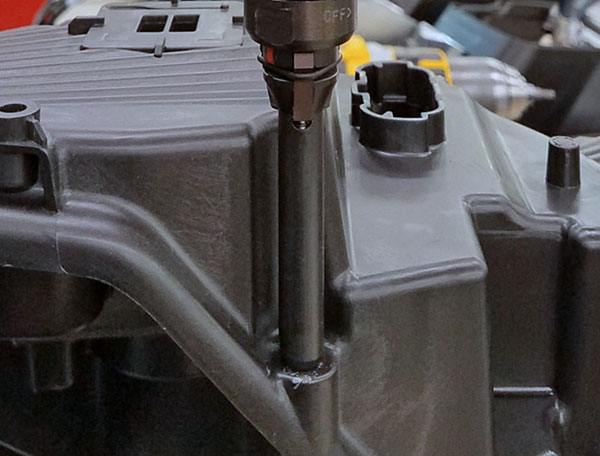

Visumatic’s most ergonomically advanced handheld system, the VZP’s superior, comfortable handling makes assembly easy, and is great for tough to handle applications. Its extended bit tooling makes it an exceptional choice for applications that have unique or tight clearance issues. The VZP accepts the fastener in the main body, then the powered bit extends the screw, making placement easy.

The Visumatic Advant-edge

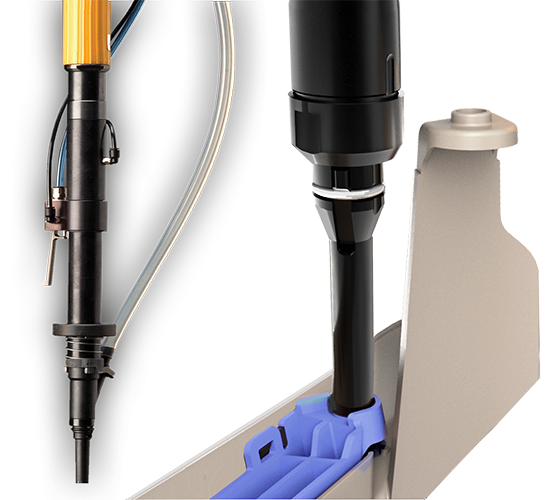

- Extension bit helps operator placement and productivity

- Accepts the fastener in the main body of the nosepiece

- Strokes the fastener to the driving position

Tooling practically self-aligns thanks to the thoughtfully engineered nosepiece design, increasing operator productivity and acceptance. The VZP virtually goes through the motions for the operator, guaranteeing a short learning curve for new operators

The VZP Extension Bit screwfeeder is engineered for your part, with the right choice of:

- DC Electric Torque Control Driver Motor System

- Nosepiece: Jaw or Fin-Jaw

- Feeder Escapement: Standard, Cam, or Finger

Improved Productivity. Ergonomically Balanced. Greater Acceptance.

CASE STUDY

Zero Push Screw Feeding & Driving Machine Topples Tough Assembly

Tight tolerance screw driving locations and deep recess always pose challenges when hand-assembling products. An automotive manufacturer recently dealt with this during a new model release incorporating bold design changes to injection molded parts. While visually stunning, the new components were tough to assemble because of greater surface complexity and blind driving holes.