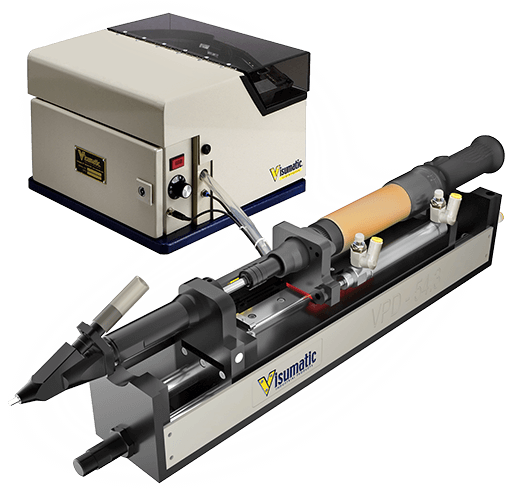

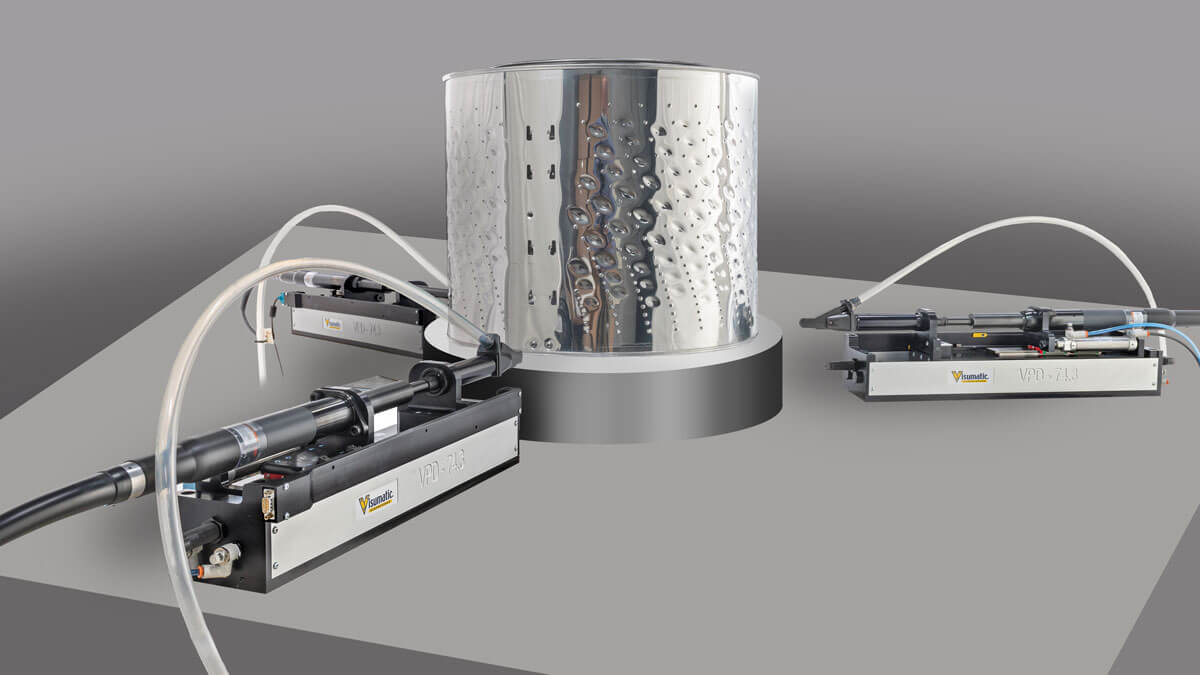

VPD Power Driver

Application: Our #1 selling automatic feed screwdriving system to install fasteners over a wide torque range.

Visumatic’s most popular “Plug-n-Work” screw feed and drive spindle for machine builders. The VPD Power driver provides independent tooling advance and bit stroke action for immediate functionality.

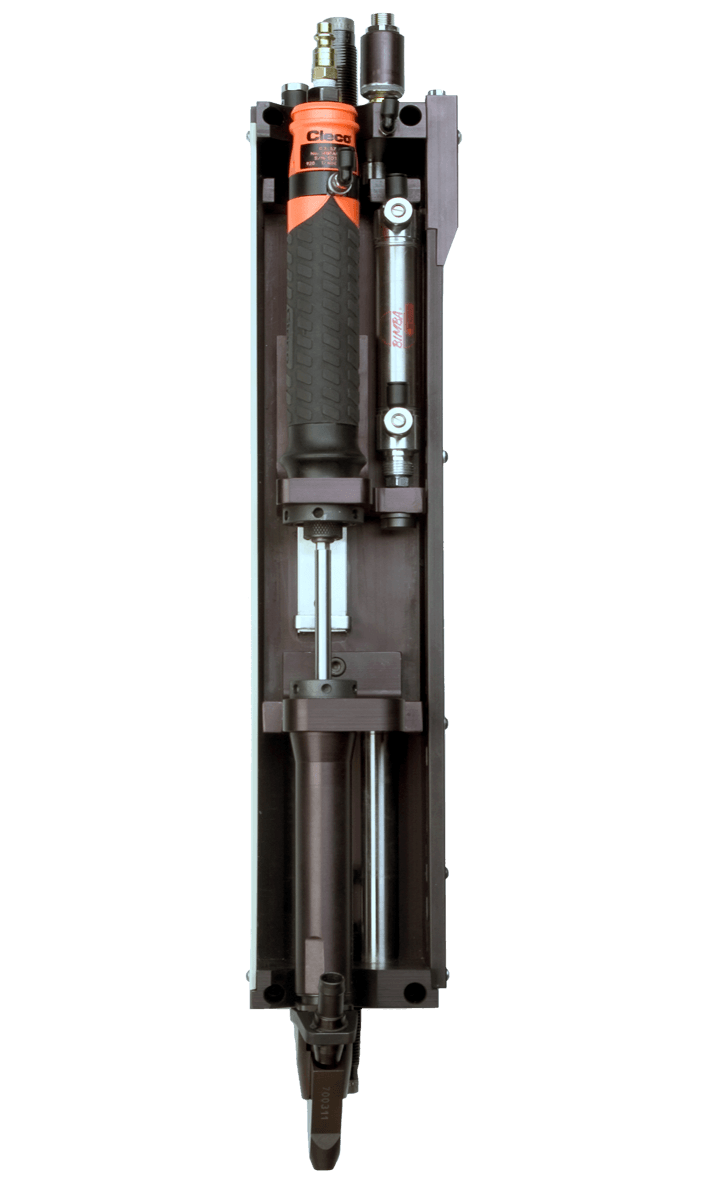

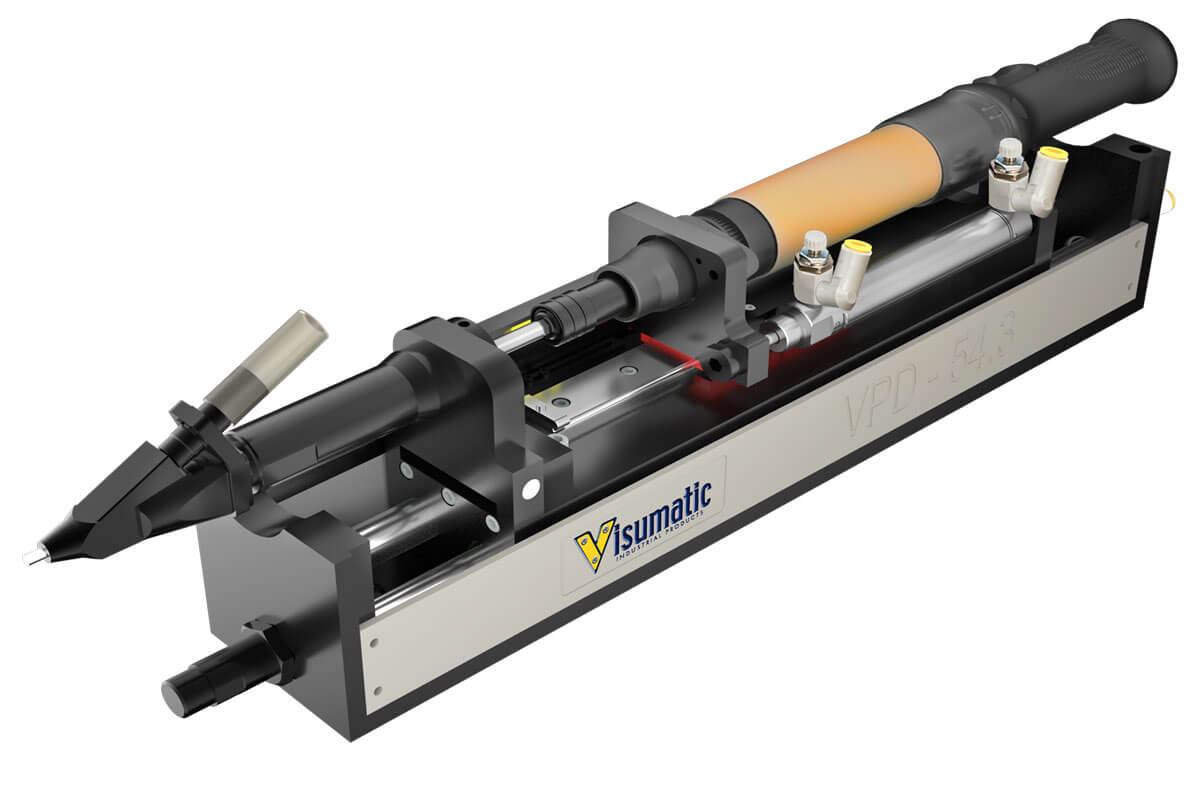

The carriage strokes the drive module towards and away from the target location, while the independently controlled bit assembly strokes the screw into the part. Each axis is discretely measurable with the integrated slide position sensors. Heavy duty bearings wear like iron ensuring smooth, accurate, and consistent motion.

The Visumatic Advant-edge

- Integral manifold and I/O port simplifies integration

- Delivered ready to plug and work.

There’s more to our excellence than efficiently and reliably driving fasteners. The design features and easy integration of our systems speak to the worry-free maintenance and low cost of ownership. Rugged internal cylinders with included flow controls deliver the market’s longest, most precise duty cycle.

Quick Bit Change

The tilt-away nosepieces allow for easy maintenance bit changes. A single attachment point releases the bit assembly completing a bit replacement in under 60 seconds!

Our engineered tooling tip nosepieces are designed to fit your part surface geometry for repeatable screw installation. Paired with our reliable Model 94 feeder, the VPD screwdriving system is the machine builder’s quiet capable partner for fastening automation.

Visumatic can integrate any brand torque and angle control screwdriver into the VPD spindle. If it fits the application, we have a system engineered to fit your motor. Visumatic gives you the freedom to continue using the gear already accepted by your customer.

Your build. Our Commitment.

Configuration Options

- VPD 7 Series

- VPD 5 Series

- VPD 3 Series

VPD 7 Series

7 Series Power Driver for Heavy Duty Screwdriving

Our best-selling screwdriving system for high torque applications. Robust design supports final torques up to 350 Nm.

Tooling tips engineered to interface with part surface geometry for repeatable rundown efficiency.

VPD 5 Series

5 Series Power Driver

The perfect fit standard duty screwdriving spindle for most fastening applications.

VPD 3 Series

3 Series Power Driver for Light Duty Screwdriving

Built for production in low to extremely low torque applications.

CASE STUDY

White goods manufacturer smashes productivity barriers

An appliance manufacturer’s in-house build group was looking to clear the bottle neck on their washing machine assembly line.