Automating an “Impossible” Bolt with Oversized Captivated Washer

Application Spotlight

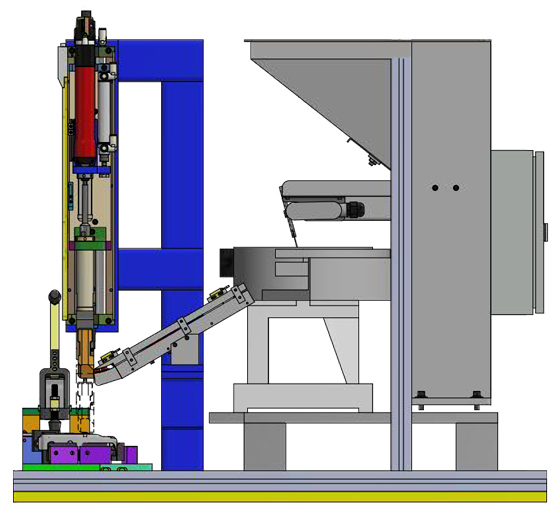

Visumatic delivers on an automated fastening promise to a metal stamping manufacturer. Their end-user asked them to do some value-add by producing a completed assembly instead of loose parts. The application required installing a single metal bolt with an over-sized captivated washer to a discreet torque in a multiple part stack up.

The bolt/washer combination was basically a square, which violates the ideal 1.2 bolt length to washer width ratio. Reaching deep into our bag of fastening tricks, Visumatic engineered a track feed system capable of repeatably feeding and driving this troublesome creature.

The system married a stainless steel bolt feeder, track feed escapement mechanism, and our standard VPD Power Driver spindle with modified nosepiece. The bolts were direct fed with hard tooling the entire way to the nosepiece assembly, eliminating transition points that can frustrate a standard blow-feeding approach.

Watch this tabletop fastening setup making parts in a new bolt driving QC video straight from Visumatic’s factory floor.

You can see the full range of tabletop screwdriving assembly machines on Visumatic’s website page.