Automation Group Nails Proof of Concept with Cobot Screwdriver Assist

Machine Builder Spotlight

An appliance manufacturer purchased a VLB-900 handheld automatic screwdriver to speed up production on a fan assembly. The process improvement engineer began working with their automation group to provide tooling support. As a result, they began exploring the idea of taking automation to the next level using collaborative robots for this application, as well as the next targeted high-volume product on their line.

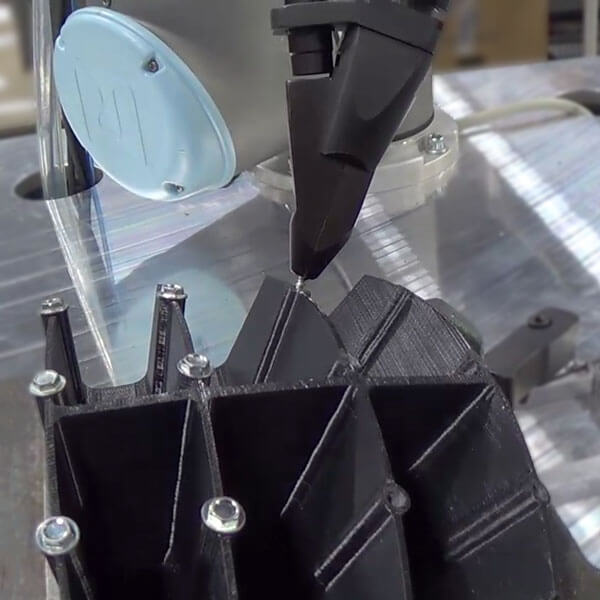

They scheduled a video call with a Visumatic applications engineer to review the scope of work and brainstorm ideas for appropriate fastening technology solutions. The VCM cobot screwdriver module was selected as the best fit approach allowing them the greatest product flexibility down the road while delivering the ability to drive screws across an arc pattern in several consecutive off-angle fin positions.

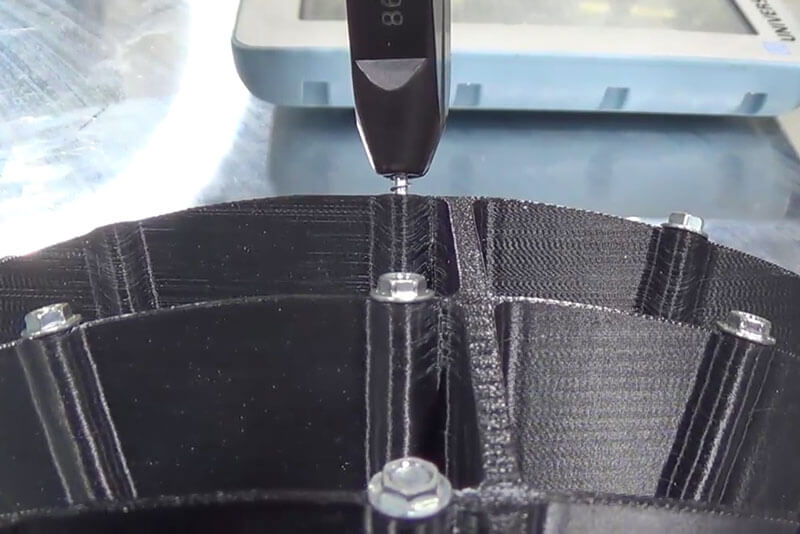

The Visumatic engineer team mounted a VCM module capable of automatically feeding and driving a socket drive hex head screw with molded into the 3-D printed prototype par. Using the QC cobot screwdriver test station, the entire team was able to witness a solid proof of concept for their requirements, allowing the automation group quickly plan their future base platform.

Now they are ready for streamlined deployment going forward. Visumatic is always ready to help with all aspects of fastening automation. Whether determining if a product is a good fit for robotic assembly, ways to make the parts more suitable, or even designing new equipment from the ground up, we have our customer’s covered.

Visumatic QC assisted with a proof of concept using our VCM-3X.2 cobot screwdriver test station.