Handheld Screwdriving System Helps a Hamper Manufacturer Double Production

Application Spotlight – VLB-900

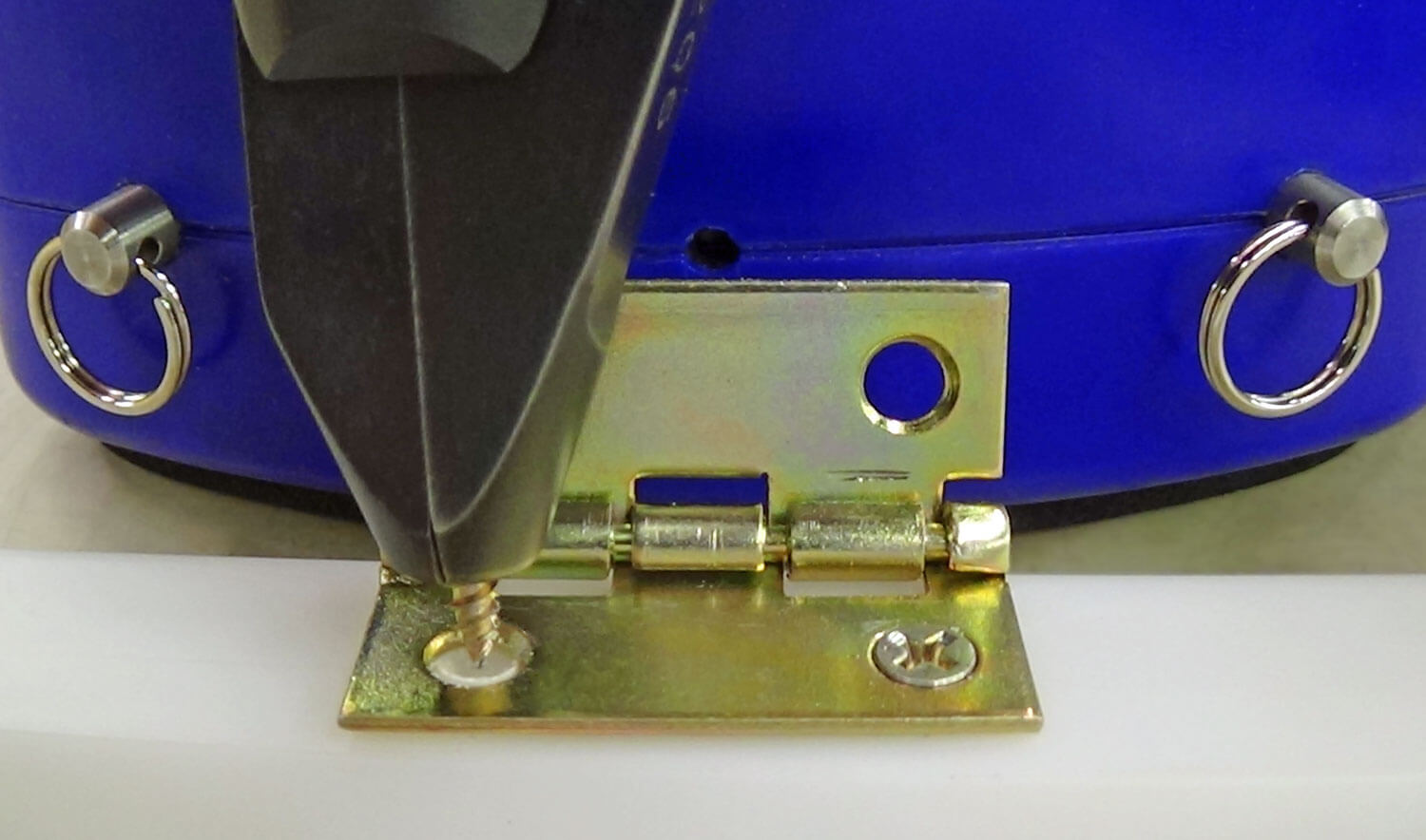

A long time Visumatic customer manufacturing laundry hampers has been experiencing sustained sales growth. Production was given the task of nearly doubling production of this product at their facility. The application is to drive two #6 flat head screws into a metal lid hinge.

They purchased their first VLB-900 automatic screwfeeder back in 2002. That unit has driven millions of screws and they have been very satisfied with its performance over the last 15 years. A new duplicate assembly work cell was approved by management to add line capacity right next to the original system.

A two-fold approach was decided upon to gear up the cells for higher production. First, upgrade/refurbish the old system to current design standards. And second, purchase a new system of the reliable modern design so that they can share common spare parts.

The VLB-900 was the right fit to attach the hinge assembly because the bit stays engaged behind the screw, allowing the operator to positively locate the through hole and align the hinge for driving. The feeder system takes care of handling the screws enabling the operators to drive both screws in a couple of seconds.

We look forward to working in partnership with these guys for another 15 year run!

Check out more application examples on our Locking Bit automatic screwfeeder page.

Standard VLB-900 Automatic Screwfeeding and Driving System

Standard VLB-900 Automatic Screwfeeding and Driving System