Zero Push Screw Feeding & Driving Machine Topples Tough Assembly

Zero Push Automatic Screwdriver

Zero Push Automatic Screwdriver

Application Spotlight

Tight tolerance screw driving locations and deep recess always pose challenges when hand-assembling products. An automotive manufacturer recently dealt with this during a new model release incorporating bold design changes to injection molded parts. While visually stunning, the new components were tough to assemble because of greater surface complexity and blind driving holes.

Operators had difficulty locating the drive positions due to tight clearances. Ergonomic strain was increased by excessive vertical stroking to reach the deep pockets. Faced with the very real issues of operator acceptance and speed of production, Visumatic was brought in to provide assistance.

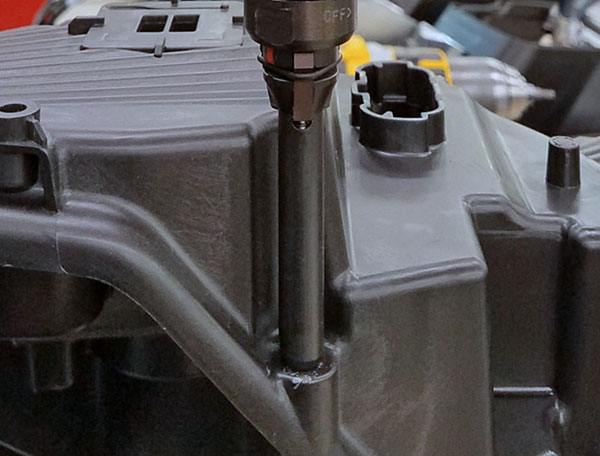

Visumatic tackled these ergonomic challenges with the VZP-900 Zero Push screw feeding and driving system. The VZP’s sleek and elegant housing provides comfortable handling with a superior feel in the operator’s hand. It requires only a light trigger touch to install the screw.

The VZP-900 delivers because it features an engineered tooling tip which guides the operator to the drive location by interfacing with the part. The machine goes through the motions for the operator, automatically extending the bit to drive the fastener in the deep positions.

Users are protected with no wrist flexing and no jamming the nosepiece against the part. There is virtually no z-axis motion for the operator.

Acceptance was accomplished by reducing the ergonomic strain and taking the guess work out of driving the screws. The operators are able to meet production demands with ease.

Making parts ~ mission accomplished.

Find more ergonomic improvement examples on VZP Zero Push screwfeeder page.